Recently updated on October 6, 2023 at 02:25 am

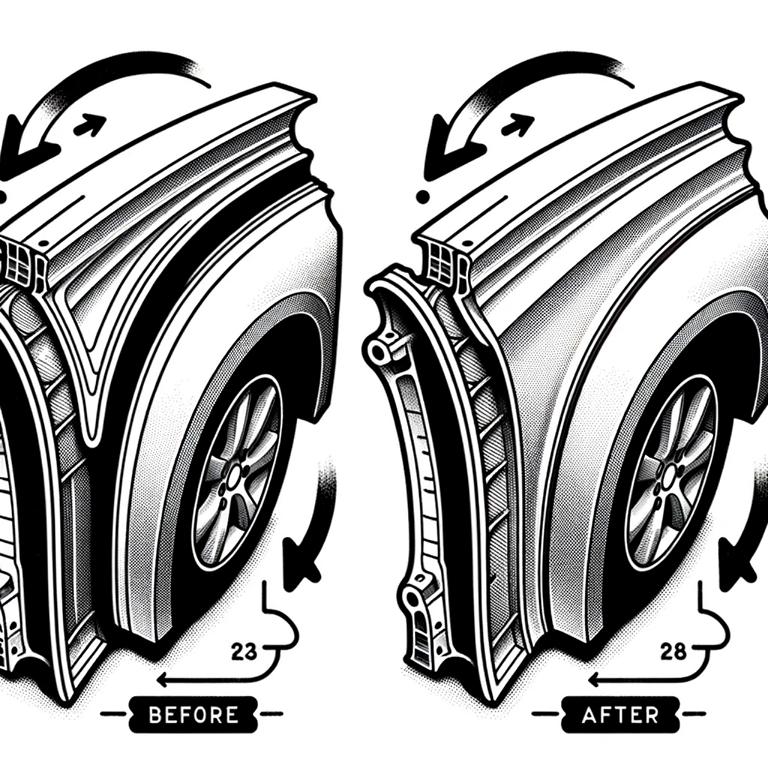

[Update: 06.10.2023] This post was updatedto take more recent information into account. In the area of car tuning, wider tires are often installed on rims with a proper drop center! But how do you fit wider tires in the wheel arch so that it also meets the legal requirements? The law requires “the wheel tread to be covered”. The answer is beading or Pull (sometimes called necking or widening) the fender! At the beading will the sometimes available edge The wheel arch is folded inwards to create a few millimeters of additional clearance for the tires. At the Pull The fender, on the other hand, widens the body towards the outside, which also allows for more freedom, but to a larger extent.

Fender flanging/pulling

In order to be able to mount wide tires with associated rims in the wheel arch of a vehicle, it is sometimes necessary to fold down or widen the fenders. This is not only the case with lowered vehicles, but also with standard chassis and lifts, it may be necessary to adapt the fenders to the body. It depends on which wheel/tire combination should accompany the change to the chassis. As already mentioned, the tires or rims must not touch the wheel arches. Also one wheel spacer may require the wheel arches to be machined. Otherwise there is an increased risk in two respects. On the one hand, the tire and rim are of course damaged, which can even lead to the tire bursting while driving.

In addition, small stones can be thrown around unhindered and damage/injure other vehicles or people. So the wheel arch needs to be worked on. With the help of folding and flanging tools, the wheel arch edge is folded evenly and relatively easily. However, manual skills and a bit of sensitivity are required. If you meet this requirement, the paint should not break during flanging and the material should survive the “tear test” of being folded over. If the work on the wheel arches is a bit more extensive, you usually cannot avoid subsequent modeling of the body and subsequent painting.

Required tool for fender flanging/pulling

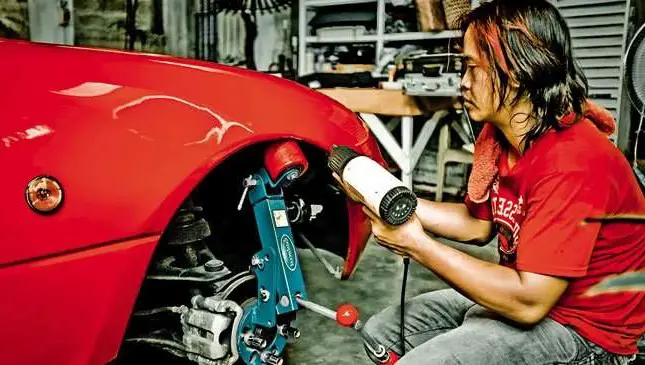

You almost always need tools when tuning and of course this is also the case when flanging the fenders. If you want to flange/tighten the fenders, you should use an appropriate roller flanging device, which is usually available from €150 (inexpensive devices starting at €50). This device makes flanging the fenders the easiest. But there is another way. Especially if you don't want to flange the fenders very often, but ideally only want to do it once on your own vehicle, it makes sense to use alternatives.

A rubber mallet is an excellent tool for fender flaring. In order to avoid dents or damage to the paint and sheet metal, a piece of plastic or hard plastic should be used to hold it up. And the paint should be warmed up beforehand in the area that is to be processed. A spray can with underbody protection and a flex are also recommended. The work isn't entirely clean, so work clothes can't hurt. Flaring fenders requires a certain amount of time and calm, so you should bring patience and a cup of coffee.

Beading the wheel arches

CAUTION:: We would like to explain you the correct way to crimp the wheel arches on the car, but point out that we accept no liability for the correctness. We neither guarantee the timeliness and correctness, nor the completeness or quality of the information provided. Liability claims against us for material or immaterial nature that may arise as a result of the use of information in this report are generally excluded to the extent permitted by law.

This variant of flanging is suitable for inexpensive vehicles and should not be done on a €100.000 car. First, all wheel arch edges must be freed from sealants and contamination. The warmer the outside temperature, the safer and easier the next steps are. If you have a garage, you should preheat it before starting work. If you don't have this option, you can, as already mentioned, use a hot air dryer to slightly warm the area that needs to be worked on.

It is important to ensure that the area remains warm. It is advisable to bring in a second person to constantly heat the paint on the wheel arch with the hot air dryer. To avoid the risk of burns or damage to the vehicle, we recommend a simple hairdryer, which is sufficient to warm the paint and make it flexible for changing.

Rubber hammer is useful when fender flaring/pulling!

In the next step the edge is folded over. The exact impact force must be found with the rubber mallet. Too little force will not fold the edge and too much can damage the paint and bodywork. It is best to wrap the plastic piece with a cloth before holding it against it. Any resulting cavities should be filled with sealant. The edges should not be folded over too tightly, as this could cause the paint to crack despite the heat. If damage to the paintwork occurs despite all measures, this should be treated with rust protection and cavity sealing. The edges should also be treated with underbody protection.

1. What is meant by flanging on fenders?

- In the Flaring of fenders it is a sheet metal processing technique. The aim is to process the edges of a sheet metal - here the fender - to create more space in the wheel arch, especially in lowered vehicles or those with larger tires.

2. How much does fender flanging cost?

- The cost of fender flaring can vary. As an example, with a service provider like “Rieger and Ludwig”, the price for flanging is: about 80 to 200 EUR per axle.

3. How does flanging work?

- Flaring involves this Folding the sheet metal edges, often on the fender to create additional space for larger wheels. This involves bending and stiffening the edge of the sheet, often by applying heat, to make the material more flexible.

4. What is a flaring tool and what is it used for?

- An Flaring tool or device helps to bend the edges of the sheet, either manually or mechanically. Special flanging devices allow the fender edges to be placed on the inside and the wheel arch edges to be folded over in order to be able to pull the bodywork outwards.

5. Why is flanging the fenders necessary?

- Flaring is often necessary Lowering or wheel/tire size changes to ensure that the wheels have adequate clearance and do not drag on the fender, especially under full steering or during suspension.

6. Can flanging cause damage to the vehicle?

- Yes, it can happen that the flanging, especially the pulling of the body, is too Paint damage can lead. This should be remedied immediately to avoid corrosion.

Example process: flanging & folding fender edges

- Thorough preparation is necessary before the actual flanging process.

- Treatment of metallic areas: Open metallic areas should be treated with rust converter before flaring to prevent future corrosion.

Carrying out the flanging

- Heating the sheet metal: A hot air dryer can be used to warm up the sheet and make it more malleable.

- Application of the flaring device: Carefully work along the wheel arch with the flanging device to gradually fold the sheet metal over.

Check and correction

- visual verification: After the flaring process, careful inspection is necessary to ensure that there is no damage or unwanted deformation.

- Free movement test: You should check whether there is enough space between the wheel and the mudguard by folding or similar methods.

aftercare

- Any paint corrections and protection: To prevent rust, exposed metal areas should be treated correctly immediately.

Conclusion: combine aesthetics and function

Flaring and pulling makes it possible to make individual changes to the vehicle, be it for aesthetic reasons or to meet specific driving requirements. It is essential to pay attention to precise execution and subsequent care in order to enjoy the vehicle in the long term.

Of course that had not happened yet!

tuningblog has countless other articles on the subject of car and auto tuning in stock. Do you want to see them all? Just click HERE and look around. In part, we would like to provide you with news but also off the tuning.

"Tuningblog.eu" - we keep you up to date on the subject of car tuning and car styling with our tuning magazine and we present you the latest tuned vehicles from all over the world every day.

tuningblog.eu Your magazine about tuning the car

tuningblog.eu Your magazine about tuning the car