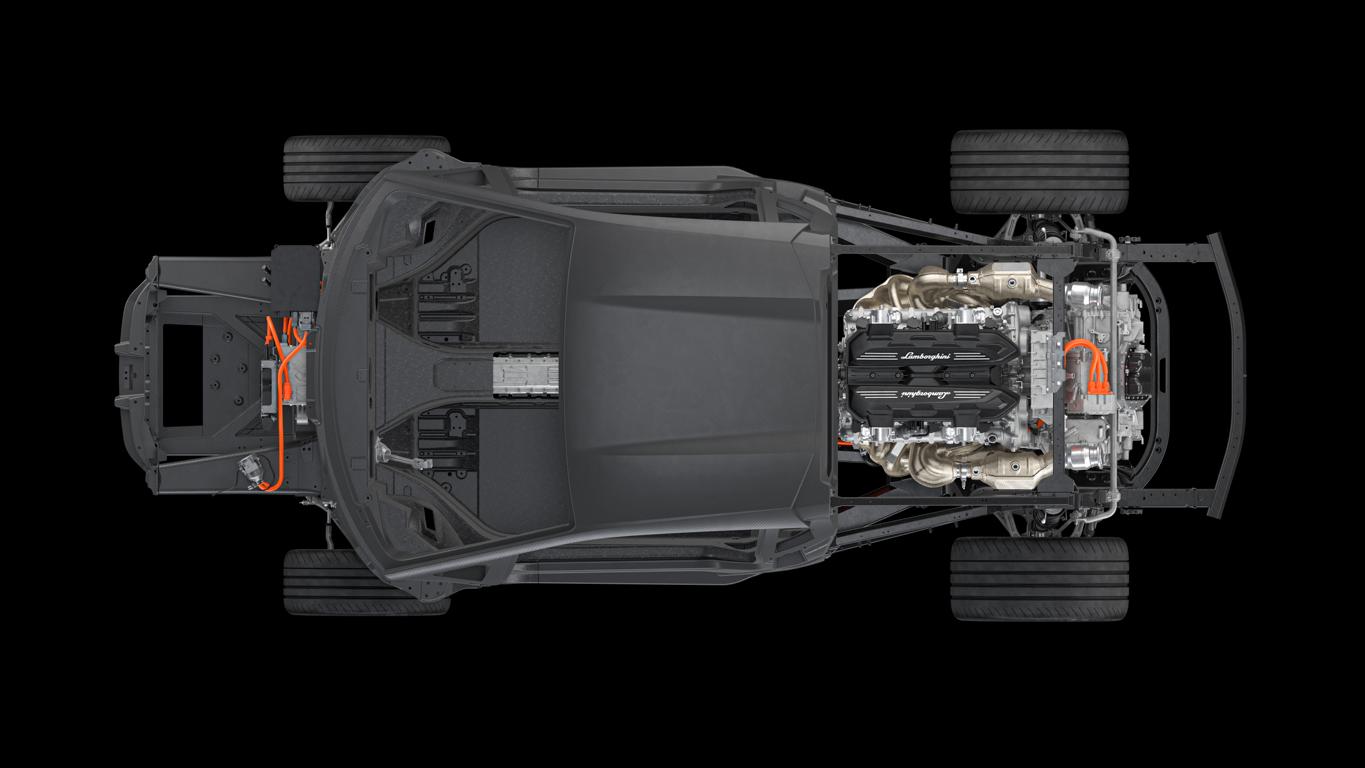

Automobili Lamborghini has stood for pioneering innovations in car manufacturing since it was founded 60 years ago. A few weeks before the presentation of the first V12 plug-in hybrid HPEV (High Performance Electric Vehicle), the automaker from Sant'Agata Bolognese is presenting a technical solution that is unique in the automotive industry. The body shell of the LB744 is designed as a monofuse layer, a structural concept inspired by aviation. The entire monocoque is made of a variety of carbon fiber composites, and the front end is made exclusively of forged composites for the first time. This composite material made of short carbon fibers and epoxy resin was patented by Lamborghini in 2008 and has been used in structural components ever since.

Lamborghini LB744

- Introduction of the innovative monofuse layer, an aeronautical-inspired monocoque concept made entirely of carbon fiber

- First super sports car with a front end made entirely of forged composites

- Greater strength and torsional rigidity with significant weight savings

The monofuselage structure increases the vehicle's torsional rigidity, reduces weight and thus improves driving dynamics. On top of that, the LB744 is the first super sports car with a front end made entirely of carbon fiber, even the conical impact absorbers in the front of the vehicle are made of forged composites. This design makes the component much lighter than a comparable metal structure and still ensures a significantly higher energy absorption - it is twice as high as the aluminum front end of the Aventador Ultimae.

Overall, the monofuselage chassis of the LB744 is ten percent lighter than the body shell of the Aventador, and the front end even weighs 20 percent less than the comparable aluminum assembly of the predecessor. The torsional rigidity now reaches the peak value of around 40.000 newton meters per degree: an increase of 25 percent compared to the Aventador and a guarantee for enormous dynamic resilience.

The design idea behind the development of the monofuse layer is based on the greatest possible integration of components. This approach is favored by the extensive use of Forged Composites technology and the development of the one-piece rocker ring. The curved, ring-shaped component made of CFRP (carbon fiber reinforced plastic) forms the supporting structure of the vehicle, enclosing and connecting the Forged Composites® elements such as the monocoque, the bulkhead and the A-pillars from below. Such use of carbon fiber components makes the LB744 unique in the supercar segment.

The production of Forged Composites® components is more efficient and sustainable because less energy is required to cool the systems and less waste is produced.

The classic, no less efficient technology of autoclave composite production with carbon prepreg was retained for the roof construction. The production in the autoclave meets the highest technical, aesthetic and qualitative requirements and also benefits from Lamborghini's highly specialized hand lamination process. This high level of craftsmanship is the result of years of quality-oriented in-house production of composite components. In addition, this production method makes it possible to respond even better to the individualization wishes of customers.

Rear carriage made of high-strength aluminum alloys

The rear end consists of high-strength aluminum alloys, using extrusion and hollow casting techniques. The dome bearing mounts, the strut mounts, the rear wishbones and the suspension of the drive train are integrated directly into a hollow cast component. This significantly reduces weight, increases rigidity and minimizes the volume of the welds. The AIM era of vehicle production begins at Lamborghini with the LB744: AIM stands for automation, integration and modularity. Automation refers to the introduction of automated and digitized processes in material processing. The traditional Lamborghini craftsmanship is still preserved, for example in the area of composite materials.

The integration consolidates multiple technical functions into a single component, made possible by the advancement of the compression molding process. Preheated polymers are used to produce a wide range of plastic parts of varying length, thickness and complexity. This ensures optimal integration of the components with maximum torsional rigidity. Finally, modularity refers to making the applied technologies modular and therefore more flexible and efficient in order to meet all product requirements and properties.

Of course, that wasn't the end of it!

tuningblog has countless other articles on the subject of car and auto tuning in stock. Do you want to see them all? Just click HERE and look around. In part, we would like to provide you with news but also off the tuning. In our category Tips, products, information & Co We have reviews of car or accessories manufacturers, new ones Tuning Wiki Terms or one or the other Leak veröffentlicht. Just click on one of the following posts!

other related posts

|

BLE sensors: everything about Tesla's idiosyncrasy when measuring tire pressure! |

|

tuningblog.eu Your magazine about tuning the car

tuningblog.eu Your magazine about tuning the car