The road trip reinterpreted: Innovative technology concept for series production! Range and efficiency are decisive factors in the age of electromobility. Long-range electric cars are also suitable for long journeys and thus for long road trips. This once again increases their acceptance. High efficiency also makes it possible to use a smaller and therefore lighter battery in order to achieve more with less. Mercedes-Benz is doing pioneering work here, as exemplified by the EQS as the current range leader. In a test by the renowned American automobile information service Edmunds, an EQS 450+ with 245 kW (combined power consumption WLTP: 19,8-15,7 kWh / 100 km; CO₂ emissions: 0 g / km)[1] 422 miles on one battery charge. That's 77 miles more than any other electric car tested before.

Mercedes Vision EQXX

With the VISION EQXX, Mercedes-Benz is now taking the next step. According to internal, digital simulations, it can be assumed that the technology carrier will travel over 1.000 kilometers in real road traffic with a single battery charge[2] will go far. This would take it to a new level in terms of range. In addition to increasing efficiency, resource conservation and the best possible environmental compatibility were equally important development goals. That is why the Mercedes-Benz engineers chose a holistic approach.

Starting with the improvement of all components of the ultra-modern electric drive train as well as the use of lightweight materials and sustainable materials. In addition, there are other efficiency measures, from the extremely low rolling resistance tires to the sophisticated aerodynamics (cW 0,17) through to the use of the latest software. The result: The VISION EQXX overcomes the previous technological limits and sets the new standard for energy efficiency.

“The Mercedes-Benz VISION EQXX shows how we imagine the future of the electric car. In just one and a half years we have developed the most efficient Mercedes of all time - with an energy consumption of less than 10 kWh per 100 kilometers. The VISION EQXX has a range of more than 1.000 kilometers2 on a single charge - powered by a battery that would fit in a small car. It underlines the direction in which our entire company is developing: We will build the most desirable electric cars in the world. " Ola Källenius, Chairman of the Board of Management of Daimler AG and Mercedes-Benz AG

VISION EQXX - designed for the road trip to electromobility

“Road trips” have been an integral part of the cultural heritage for at least 70 years. And with good reason. In books, films and music, they provide the material for exciting stories about people and their automobiles. Roadtrip Stories are about freedom, individuality and discovering the world on four wheels. Put a needle in the map - and drive off. The urge to explore, discover and enjoy the world beyond our horizons is in human nature. If there is also a portion of pioneering spirit, visions can become reality.

The path to electromobility is also a road trip - exciting, challenging and with one clear goal in mind: innovation. The Mercedes-Benz VISION EQXX is a vehicle that was designed for this special transformation road trip. It provides answers to the demands of a modern generation of customers who demand both: emotionality and innovation. As a software-optimized prototype, the VISION EQXX is part of a far-reaching technology program that Mercedes-Benz launched to build the most efficient electric car in the world. The inventor of the automobile relies on the latest digital technology and combines it with the pioneering spirit that shapes the brand's DNA, the agility of a start-up and the pace of Formula 1. The result is an efficiency champion who can do more with a single battery charge than 1.000 kilometers[3] comes far. This corresponds to an energy consumption of less than 10 kWh per 100 kilometers or an energy efficiency of more than six miles per kWh.

With the VISION EQXX, Mercedes-Benz has also set new records for aerodynamics and weight reduction and implemented a software-based vehicle concept that redefines the road trip for the electric age. Instead of simply increasing the size of the battery, the cross-divisional international development team concentrated on maximizing long-distance efficiency - from drive efficiency and the battery's energy density to aerodynamics and lightweight construction. At the same time, the VISION EQXX is a progressive interpretation of the basic Mercedes-Benz principles of modern luxury and sensual clarity.

"The technology program behind the VISION EQXX will redefine and enable future models and vehicle functions from Mercedes-Benz", says Markus Schäfer, Member of the Board of Management of Daimler AG and Mercedes-Benz AG, Chief Technology Officer responsible for Development and Purchasing. “As a 'Halo Car', the VISION EQXX clearly establishes Mercedes-Benz as the brand that combines luxury and technology in the automotive world and beyond. And the way in which we developed this technology program is just as revolutionary as the vehicle itself. For the VISION EQXX, the best minds from our research and development centers worked together with engineers from our Formula 1 and Formula E teams. They prove that innovations from motorsport - where the drive trains are already highly electrified - are of direct relevance to the development of road vehicles. We question the current development processes with an innovative spirit and unconventional thinking. This is our way into the future. "

With the VISION EQXX, Mercedes-Benz is breaking new ground. The research vehicle represents a courageous yet absolutely realistic step into the future of electric vehicle technology. In addition to its outstanding energy efficiency when driving, the technology platform also offers meaningful answers to other pressing questions. For example, the CO2- Significantly reduced footprint through the use of sustainable materials. The UI / UX has a completely new, one-piece display that extends over the entire width of the interior. User interface elements support the seamless interaction between driver and vehicle. Among other things, through Artificial Intelligence (AI), which mimics the functioning of the human brain. The software-controlled development process is revolutionizing the way in which electric cars will be developed in the future.

The VISION EQXX is the result of a comprehensive program that provides a blueprint for the future of automotive engineering. Many of the innovative developments are already being integrated into production, some of them also in the next generation of the MMA, the modular architecture for compact and mid-range vehicles from Mercedes-Benz.

A car with a mission - the most efficient Mercedes-Benz ever built

Efficiency means doing more with less. The VISION EQXX is packed with efficiency improvements, realized through a mixture of advanced technology and passionate teamwork. As a road-legal research vehicle, the VISION EQXX consumes less energy and resources and still offers more of everything: more range, more luxury and more comfort. In addition, digital tools and a software-based approach significantly reduced the time required for development.

#EnergyWizard: Measures to increase efficiency lead to extremely low consumption of less than 10 kWh per 100 km (corresponds to more than six miles per kWh).

#ElectricDrive: The radically new drive concept developed by Mercedes-Benz achieves a benchmark efficiency of 95 percent from the battery to the wheels.

#RangeBuster: More than 1.000 km (over 620 miles)[4] with a single battery charge on public roads enable relaxed long-distance journeys.

#EnergyDensity: Know-how from Formula 1 helped the battery experts to compress the energy storage device of the EQXX into an extremely compact format. The battery pack of the VISION EQXX stores almost 100 kWh of energy with 50 percent less volume and 30 percent less weight than the world's best battery pack of the EQS so far in this regard.

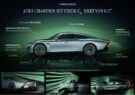

#AeroChamp: Outstanding work in the fields Aerodynamics and exterior design enable a benchmark drag coefficient of 0,17[5].

#SustainableMaterials: Innovative recycled and plant-based materials avoid waste in landfills and reduce CO2-Footprint.

#UpliftMindset: A dedicated team of Mercedes-Benz engineers worked with the racing specialists from High Performance Powertrains (HPP) and Mercedes-Benz Grand Prix (MGP) to develop a highly efficient and compact electric drive train and a lightweight battery housing.

#BionicEngineering: Inspired by natural shapes and in collaboration with innovative start-ups, the engineers used advanced digital tools to reduce weight and reduce waste. With the help of 3D printing, they were able to save excess material.

#SolarPower: Ultra-thin roof panels feed the battery system and provide an additional range of up to 25 km.

#RollingEfficiency: Tires with extremely low rolling resistance and improved aerodynamic geometry, in combination with lightweight magnesium wheels, ensure greater range.

#BrakingLightly: Lightweight aluminum alloy brake discs help reduce the weight of the VISION EQXX.

#EfficiencyOnTheRoad: The all-electric chassis with a lightweight F1 subframe brings racing efficiency to the road.

#HumanMachineMerge: An intuitive user interface and a user experience with support for efficient driving form the perfect interface between people and vehicles in the electric age.

#SensualPurity: A team of exterior and interior designers focused on electromobility created the #EQ Halo Car for the fully electric future. The VISION EQXX underlines the claim of Mercedes ‑ Benz to build the most desirable automobiles.

#FastTechProg: From the proverbial blank sheet of paper to the streets in just 18 months. The VISION EQXX is part of a technology program that can bring innovative solutions to series production readiness faster than ever before.

#Transformation: The VISION EQXX shows the change from Mercedes-Benz to a purely electric and software-based company.

#SoftwareDriven: Software-driven approach as the key to success in achieving efficiency goals and a rapid development process, including a groundbreaking battery management system.

#GlobalResponsebleleadership: With the VISION EQXX Mercedes-Benz is increasing the pace in order to become “Lead in Electric” and to set standards for sustainable mobility.

VISION EQXX: The most important technical data at a glance[6]

| Energy content of the battery, usable | kWh | <100 |

| nominal voltage | Volt | > 900 |

| Energy consumption | kWh / 100 km

(Miles / kWh) |

<10

(> 6) |

| cw-Value | 0,17[7] | |

| Performance | kW | ~ 150 |

| wheelbase | cm | 280 |

| Gross weight of the vehicle | kg | ~ 1.750 |

Efficiency is the new currency

At its core, efficiency means achieving more with less. This is not new: Mercedes-Benz has always placed particular emphasis on the efficiency of its vehicles and has made great technological advances over the decades. Customers benefit from this through constant improvements in fuel consumption and comfort. But electromobility and sustainability goals have raised the bar for efficiency even higher.

The best-known measured variable for the efficiency of motor vehicles is fuel consumption or fuel savings. Consumption is measured in different ways depending on the country (e.g. liters per 100 kilometers, miles per gallon or kilometers per liter). Nonetheless, all units of fuel (energy) are uniformly set in relation to the units of distance. This also applies to electromobility.

Mercedes-Benz declares efficiency the new currency and thus creates a common denominator for quantifying technological development - beyond pure fuel efficiency. This not only means more range with less energy, but also more luxury and comfort with less impact on the environment and more electromobility with less waste.

In order to achieve this, the VISION EQXX pushes the limits of what is technically feasible in all areas. The prototype gives a concrete outlook on what premium efficiency looks like for the electric-digital age and what it feels like. Elegant design and intuitive operation, supplemented by advanced digital technologies, enable sustainable, electric long-distance mobility in the typical Mercedes-Benz style.

“The suffix XX complements the Mercedes-Benz brand with the X-factor of electromobility, with which it thinks across borders. XX also stands for an agile, cross-divisional collaborative development approach ", explains Markus Schäfer. "In this way, we are expanding the breadth and depth of development skills within Mercedes-Benz AG with state-of-the-art digital tools and industry-leading expertise from a large number of partner companies, start-ups and institutions around the world."

From the innovative drive train to the bionic lightweight structure, from the ingenious thermal management to the aerodynamically perfected body shape - consistently used efficiency technologies in all areas ensure extremely low energy consumption and the high real range of the VISION EQXX.

"Achieving long electrical ranges sounds easy, but it is a complex technical challenge. The easiest way is to use a larger battery. However, due to its size and weight, this leads to poorer efficiencies. It is definitely not the smartest way to go, nor is it the best use of valuable resources. With the VISION EQXX project, we have found new ways to increase the range of an electric car. And we're raising efficiency to a completely new level. "

Joerg Bartels, Head of Vehicle Integration at Mercedes-Benz AG

The speed at which the project was implemented is also exceptional: a vehicle was created from an initial sketch in just 18 months. A global, multidisciplinary team, including experts from Formula 1, worked on the development of the VISION EQXX. In mutual exchange, the team members used the latest technologies and approaches to develop progressive, highly efficient solutions with realistic potential for the near future.

Groundbreaking powertrain for the electric age

On every trip, it's the car that does the job. It “makes the route” while the driver and passengers can enjoy the journey. The VISION EQXX focuses on the long haul, and efficiency is the be-all and end-all.

The highly efficient electric drive train provides an output of up to 150 kW of the VISION EQXX for outstanding endurance over long distances. The prototype is more than the sum of its parts. It is an engineering total work of art. The team pursued the clear goal of developing an electric drive train with a unique combination of efficiency, energy density and lightweight construction. Above all, there is a number that stands for this: 95 percent efficiency. This means that up to 95 percent of the energy stored in the battery arrives at the wheels. For comparison: in a vehicle with an efficient combustion engine it is around 30 percent, in an average (human) long-distance runner around 50 percent.

The Formula 1 experts at Mercedes-AMG High Performance Powertrains (HPP) in Brixworth (Great Britain) know how to use every kilojoule of energy. In close cooperation with the racing engineers, the research and development department at Mercedes-Benz has redesigned the drive train and reduced system losses.

"One of the best ways to increase efficiency is to reduce losses," explains Eva Greiner, chief engineer for electrical drive systems at Mercedes-Benz. “We have worked on every part of the system to reduce energy consumption and losses through system design, material selection, lubrication, and thermal management. And our excellent simulation tools helped us to quickly find out what works and what doesn't. "

The electric drive system in the VISION EQXX is an independent unit consisting of an electric motor, gearbox and power electronics with a new generation of silicon carbides. The inverter is based on that of the upcoming Mercedes-AMG Project ONE hypercar.

Battery development on a new level in cooperation with HPP

For the VISION EQXX, Mercedes-Benz and the HPP team have developed a completely new, compact and light one Battery pack developed that achieves a remarkable energy density of almost 400 Wh / l. This benchmark value made it possible to install a battery with almost 100 kWh of usable energy in a space-saving manner.

"We have packed the energy of the EQS into the dimensions of a small car"says Adam Allsopp, Advanced Technology Director at HPP. “The battery has almost the same amount of energy as the EQS battery, but is only half the size and 30 percent lighter. When developing the battery management system and the power electronics, great importance was attached to reducing losses. In reaching this efficiency milestone, we learned a lot that will be incorporated into future development programs. "

The chemistry of the anodes also plays a major role in the increased energy density. Their higher silicon content and their composition make it possible to store significantly more energy than the previously available anodes. Another advantage that enables the impressive energy density is the high level of integration of the battery pack. This platform, which was jointly developed by Mercedes-Benz R&D and HPP, creates more space for the cells and reduces the overall weight. The separate compartment for the electrical and electronic components (EE), the so-called OneBox, which also offers advantages during installation and removal, also provides more space for the cells. In addition, the OneBox contains innovative safety devices with energy-efficient operation. They consume significantly less energy than the corresponding components in current series electric vehicles.

With the aim of exploring the limits of what is technically feasible at all levels, the battery development team also worked with an unusually high voltage of over 900 volts. The research area also benefits from this in the development of power electronics. The team was able to collect a lot of valuable data and is currently evaluating the potential benefits for future series production.

Compact, light and highly efficient - these are convincing, but by no means all, advantages of the new battery. It also marks further progress in terms of sustainability, not least thanks to its design. The lightweight cover was developed jointly by Mercedes-AMG HPP and the chassis partners of Mercedes Grand Prix. The component consists of a new, sustainable composite material. It is obtained from sugar cane waste, reinforced with carbon fibers and is also used in Formula 1. The battery also has what is known as active cell balancing. It ensures that the energy is drawn evenly from the cells while driving, which further increases the system efficiency. In total, the battery weighs around 495 kilograms, including the OneBox.

For the optimal temperature balance: innovative heat management system

Physics defines heat as “energy that is transferred between two systems due to different temperatures”. If this energy remains unused, there is a loss of heat, which reduces the overall efficiency. To counteract this, the VISION EQXX received an advanced thermal management system. It preserves the thermal energy and at the same time reduces the cooling resistance. Both have an effect on efficiency.

This innovative solution is based on the Mercedes-Benz "cooling-on-demand" concept, which was further developed for the VISION EQXX. This ensures optimal cooling in all operating states. Since the electric drive generates very little waste heat thanks to its high level of efficiency, the heat management system of the technology carrier could be kept very compact and light. The perfectly coordinated interaction of air flaps, coolant valves and water pumps ensures that the drive train, including the power electronics, always works in the optimal temperature window. And that with minimal energy consumption. The reason for this is the effective combination of the airflow management system with a cooling plate, which is placed in the underbody of the vehicle and uses the airflow at this point.

This cooling element is the most aerodynamically efficient solution for regulating the temperature balance of the drive train. Under normal conditions, it can increase the range of the vehicle by up to 20 kilometers. The cooling system only shifts up a gear when the outside temperature is very high or when the driving style is dynamic. The normally closed flaps on the front of the VISION EQXX open at higher temperatures and introduce additional cooling air via an air duct system. The inlets are located along the high pressure zone of the front bumper. The outlets are located in the low pressure zones on the bonnet.

The advantage of this demand-controlled cooling: When the flaps are closed, the cWValue remains low, which is the case most of the time. With the flaps open, the drag coefficient only increases by seven points (0,007). If the vehicle needs to be cooled while stationary, an additional cooling fan switches on (thermal efficiency mode).

Keeping the heat - a heat pump uses ambient and waste heat

The innovative heat pump of the VISION EQXX uses the heat generated by the drive system and present in the outside air to heat the interior. Thanks to its excellent efficiency, it can significantly increase the range of the battery, for example in colder regions of the world.

The so-called multi-source heat pump draws heat from the ambient air via an external heat exchanger. This new additional function increases the operating temperature range. This is particularly effective when it comes to heating up the interior quickly at low temperatures. And in order to utilize even the last remaining heat, it uses the "evaporator enthalpy" to dehumidify the ambient air. Enthalpy is the latent energy that is released as heat when water vapor in the air changes its physical state from gaseous to liquid.

The sun rises - more range thanks to solar power

The sun is the original source of all energy on earth, but it mostly reaches the consumer in a roundabout way - via plants, for example. For the development engineers at Mercedes-Benz it was therefore an obvious choice to work without “intermediaries” and to go straight to the spring in the sky in order to fill up with additional energy.

The electrical system, which supplies many ancillary units in the VISION EQXX with electricity, draws additional energy from 117 solar cells on the roof. It was developed in cooperation with the Fraunhofer Institute for Solar Energy Systems ISE - Europe's largest research institute for solar energy. The bottom line is that the reduced energy requirement of the high-voltage system leads to a greater range. In a single day and under ideal conditions, this can result in an extra range of up to 25 km for long-distance journeys.

Mercedes-Benz and its partners are working on using solar energy to charge the high-voltage system as well.

Design and aerodynamics - an ingenious conflict solution

One of the greatest "efficiency brakes" is particularly noticeable on long stretches on the open road - although it is invisible: the aerodynamic drag. It can have a major impact on the range. During a normal long-distance journey, a conventional electric vehicle uses almost two thirds of its battery capacity to overcome air resistance. This is not the case with the VISON EQXX with its extremely low drag coefficient of 0,17[8] comparatively easy.

Aerodynamics and design often have opposing interests, as Gorden Wagener, Chief Design Officer Daimler AG and Mercedes-Benz AG, explains: “The VISION EQXX is a vision of the future that embodies the pursuit of a new level of luxury from Mercedes. As designers, we always think of the connection between technology and aesthetics. For us as designers, the aerodynamics of the VISION EQXX embodies this fusion of technology and aesthetics. Through our philosophy of sensual clarity, we have created unique proportions that combine beauty with efficiency. The resulting body flow delivers revolutionary aerodynamics. The fact that the end result turned out so beautiful underscores the ability of our design team to work closely with our aerodynamics experts. "

Mercedes-Benz designers and aerodynamicists traditionally work very closely together to combine the attractive design language typical of Mercedes with excellent flow properties. The list of Mercedes models with the world's best aerodynamics is long: it ranges from the W 125 from 1937[9] via the 540 K "Streamline" from 1938, the C111[10] from the 1970s, the CLA from 2013 with cW 0,22 up to the current EQS with 0,20. Another aero champion is the Concept IAA from 2015[11]. With numerous active aerodynamic elements for the first time, the four-door coupé achieves an extremely favorable drag coefficient of cW 0,19 - paired with typical Mercedes, unmistakable design.

The VISION EQXX owes its outstanding cWValue of 0,177 the flow-like basic shape, the innovative, aerodynamically neutral cooling plate in the underbody and the complex integration of passive and active aero elements into the body. In order to achieve these convincing results in a short time, the interdisciplinary team used advanced digital development tools. This made it possible for the first time to reduce air resistance and at the same time combine the sensual clarity of the Mercedes-Benz design philosophy with the practical properties of a road vehicle suitable for everyday use.

"It usually takes about a year to complete the form finding", says Teddy Woll, Head of Aerodynamics at Mercedes-Benz. “We had less than half the time for the VISION EQXX. Lean, agile processes and sophisticated digital tools made collaboration much easier and enable faster decisions. In addition, we only needed one model and much less time in the wind tunnel. "

Result of the cooperation: The VISION EQXX impresses with its elegantly flowing shape. The body surfaces run harmoniously from the front to the rear and develop powerful and sensual shoulders above the rear wheel arches. This natural flow ends in a clearly defined, aerodynamically perfectly effective trailing edge. This element is accentuated by a glossy black trim strip and underlined by the taillights.

The body of the VISION EQXX, painted in Mercedes-Benz Alubeam silver, integrates the smooth-surfaced dome of the greenhouse and flows backwards elegantly like a drop of water. The retractable rear diffuser is an impressive example of the collaboration between design, aerodynamics and technology. It is used from 80 km / h and then ensures reduced air resistance and increased driving stability. When retracted, it blends seamlessly into the body and maintains the balance, proportions and the light aesthetics of the rear end.

The big technical challenge with the rear diffuser was to prepare the apparently simple mechanism for a number of different requirements - which sometimes conflicts with the laws of physics. On the one hand, it was about combining functional reliability under all circumstances and consistent lightweight construction. In addition, the construction had to be designed in such a way that the diffuser retracts automatically and without delay in the event of a rear impact.

The VISION EQXX has a number of optically less conspicuous, but important active and passive aerodynamic details. In addition, there is its small frontal area. It is even smaller than that of today's CLA or the vehicles from smart. What is hardly noticeable at first glance: the rear track is 50 millimeters narrower than the front and ensures that the rear wheels are ideally positioned in the slipstream of the front wheels. Two ingenious details are the air curtain in front of and the air vent behind the front wheel arches. Together with the aero wheels and tires, this ingenious system closes the aerodynamic “break” of the front wheel arches almost completely. If the cooling plate is insufficient and the cooling air flaps in the bow open, air ducts direct the additional cooling air over the bonnet and leave the perfect flow in the area of the wheels and underbody untouched.

The front of the VISION EQXX is a real eye-catcher despite the small front surface. Above the shiny black radiator grille with rose gold accents, a band of light flows into the energy-efficient headlights, reminiscent of those of the EQS. Each headlight consists of two star-shaped elements, with the larger element bundling both the low beam and high beam behind a shiny center lens. This arrangement, paired with the 2D star pattern of the front bumper, gives an outlook on the details of the front design of future Mercedes-Benz models.

Efficient wheels and tires - optimized in terms of rolling resistance and aerodynamics

When developing the wheel-tire combination for the VISION EQXX, the engineers at Mercedes-Benz worked with tire experts from Bridgestone together. The technology carrier rolls on Turanza Eco tires from Bridgestone, which thanks to the light and environmentally friendly ENLITEN and ologic technology ensure particularly low rolling resistance. The tire sidewalls are aerodynamically optimized. The covers of the 20-inch lightweight magnesium forged wheels are precisely tailored to the tire format. The semi-transparent double-spoke design of these covers meets all aerodynamic requirements and at the same time reveals the rose gold accents that adorn the wheels.

New aesthetics in the interior design stage reduction and lightweight construction

The VISION EQXX is the starting shot for a new, emphatically puristic design style, which also reflects the efficiency concept in the interior design. The designers avoided complex solid bodies and focused on a few modules that express the beauty of lightweight construction. Visible lightweight structures underline this aesthetic and replace classic trim parts.

From mushrooms to vegan silk - sustainable materials in the VISION EQXX interior

Sustainable materials and organically designed design details convey a feeling of lightness and luxury. The basic principle is: maximum comfort and style with minimum weight - and that without products of animal origin.

Numerous innovative materials are used in the interior, supplied by start-ups from different parts of the world. The door handles, for example, are off the Biosteel® fiber from AMsilk manufactured. This is a high-strength, biotechnologically produced and vegan certified silk-like fabric. The particularly environmentally friendly material is being used for the first time in an automobile.

Another sustainable material that is used in the interior of the VISION EQXX is MyloTM, another certified vegan leather alternative. It is made from mycelium, the subterranean root-like structure of mushrooms. MyloTM is mainly made from renewable, naturally occurring raw materials. This completely new biotechnological material is used for details of the seat cushions of the VISION EQXX.

The leather alternative that is also used Deserttex® is a sustainable cactus-based biomaterial, which is made from powdered cactus fibers in combination with a sustainable bio-based polyurethane matrix. The leather alternative has an exceptionally smooth surface that is extremely soft to the touch. A higher proportion of cactus is planned for successor versions, whereby this material could halve the ecological footprint of conventional artificial leather.

The carpets in the VISION EQXX exist 100 percent from rapidly regrowing Bamboo fiber. This natural raw material is not only renewable, it also has a luxurious look and feel. Mercedes-Benz chose these sustainable, innovative and high-performance materials because they have the potential to replace all petroleum- and animal-based products that are currently used in automotive engineering. Mercedes-Benz is thus showing a way into the future of resource-saving luxury design that is in harmony with nature.

In addition, recycled materials are used on a large scale in the VISION EQXX. An example of this are recycled PET bottles that are used in a shimmering textile that is used in the floor area and in the door panels. In the upper area of the interior, at the transition between the doors and the headliner, the designers used Dynamic® Material. It consists of 38 percent recycled PET and creates a wrap-around effect. In the interior also comes UBQ material for use, a sustainable plastic substitute made from household waste.

"Working with these innovative, sustainable materials to design the interior of the VISION EQXX was an important and exciting, exciting experience", says Gorden Wagener. “They open up completely new ways of creativity, and the optical and haptic surfaces are exquisite. The upscale atmosphere of the interior with ambient lighting and silver, rose gold and black glossy accents is a progressive interpretation of modern luxury for the age of electric vehicles. "

Intelligent body shop - efficient and sustainable through bionic technology and modern materials

When it comes to lightweight construction, Mother Nature is the best developer in the world. In the course of evolution, it has produced the optimal design for highly efficient long-distance travelers - from monarch butterflies to arctic terns. The body developers of the VISION EQXX were inspired by nature and supplemented external know-how. The result is a particularly weight-efficient construction.

The intelligent use of sustainable materials and methods inspired by nature is known as bionic technology. It is made possible by a digital process known as bionic network design. Mercedes-Benz has a long tradition in the application of bionic technologies, which goes back to the “Bionic Car” concept study from 2005.

BIONEXXTM Cast part - optimal functionality in the smallest of spaces

The BIONEQXX element, manufactured using the aluminum casting process, is currently the largest light metal structural component at Mercedes-Benz and forms the main component in the rear of the VISION EQXX - the rear floor. Mercedes-Benz developed this complex casting in just four months using fully digital techniques and a software approach that is unique in the automotive industry. The result is optimal functionality with extremely compact dimensions.

Based on organic forms, material was only used where it is necessary for structural strength, ie where loads occur. Because: where there is no load, there is no need for material. The most important structural criterion is high rigidity and stable crash behavior. The BIONEQXX cast part offers the possibility of combining this with functional integration in an extremely light individual component and thus replaces a significantly heavier assembly made up of several interconnected parts.

Bionic simulation with a touch of Hollywood

Complex tasks in a short time - this was achieved with the help of a fully digital process that forms the blueprint for the future development of series vehicles. In addition to classic optimization techniques, the team also used a new type of cooperation model that also includes graphics and polygon modeling tools from the 3D game industry and Hollywood animations.

The software used by Mercedes-Benz engineers in the automotive sector makes it possible to identify stresses and load paths in a component. All of this is done digitally before anything is cast in metal. This innovative process significantly accelerates the development process; a bionic shell structure can be produced in half the time otherwise required.

The resulting one-piece casting has a web-like appearance with gaps in places where no structural elements are required. The rear floor of a vehicle is exposed to particularly heavy physical loads in everyday life. In addition to the torsional and bending forces caused by driving movements and payload, the rear area must withstand large amounts of water and dirt. The external partner UBQ Materials provided an efficient solution to this problem. The Israeli start-up has developed a sustainable plastic substitute that is made from waste that normally ends up in the landfill. This includes food and garden waste, but also mixed plastics, cardboard and even baby diapers. One kilogram of UBQ removes 1,3 kilograms of waste from the landfill, of which around 0,3 kilograms are water. The cooperation between Mercedes and UBQ won the “Sustainability Award in Automotive 2021” in the “Best Start-up” category [12]. The use of UBQ in the VISION EQXX shows that this material also has great potential for series production.

The openings in the BIONEQXX rear floor cast part are closed with "plasters" made of UBQ, which were produced using the 3D printing process. The so-called UBQ patches are shape-optimized and combine very high rigidity with excellent sound insulation properties. A total of 42 of these elements are built into the VISION EQXX. It is inserted into the BIONEQXX cast part using a special adhesive process. The finished unit is completely sealed against water and dirt. The component shows that this innovative design approach enables a weight saving of 15 to 20 percent compared to a conventionally manufactured component. It is a milestone in lightweight construction, especially since the material and manufacturing process meet the particularly high quality requirements of Mercedes-Benz.

BIONICASTTM Damper domes

BIONICAST is a registered trademark of Mercedes-Benz for cast parts that are constructed according to natural, bionic principles. In addition to the BIONEQXX cast part for the rear floor, the VISION EQXX also uses BIONICAST damper domes that accommodate the suspension elements in the front end. Like the BIONEQXX cast part, they also make a decisive contribution to weight reduction and save around four kilograms in weight compared to conventionally manufactured domes. The supports for the windshield wipers and the motor of the VISION EQXX are also designed according to bionic principles. This also shows the enormous potential of this future-oriented technology, which can significantly reduce weight and at the same time ensure high strength. BIONEQXX has already flowed into the series production of Mercedes-Benz models, for example in the chassis components of the new EQS.

Advances in lightweight construction, safety and sustainability through innovative materials and manufacturing processes

The VISION EQXX consists of numerous innovative materials that meet the high Mercedes-Benz standards in terms of functionality and safety. Some of these materials are already being used in the development of future series models.

The VISION EQXX is one of the first Mercedes-Benz vehicles to use the ultra-high-strength steel MS1500 for the body-in-white. The extraordinary strength of this material offers excellent occupant protection in the event of an impact, but is significantly lighter than conventional steels. The CO2-Low flat steel is made from 100 percent scrap in the electric arc furnace process. CO2-Low steel grades have recently also been used in Mercedes-Benz series vehicles and are considered to be the solution of the future. The cooperation between Mercedes-Benz AG and Salzgitter Flachstahl GmbH was awarded the MATERIALICA Design + Technology Gold Award 2021[13] in the “CO2-Efficiency "excellent.

The doors of the VISION EQXX are made of a compound material in which CFRP and GFRP components (carbon and glass fiber reinforced plastics) are combined with aluminum reinforcements. In addition to weight advantages, this construction has other advantages, in particular a balanced ratio of rigidity and deformability in the event of a crash. A new type of polyamide foam reinforces the lower edge of the door and improves energy absorption in the event of a side impact.

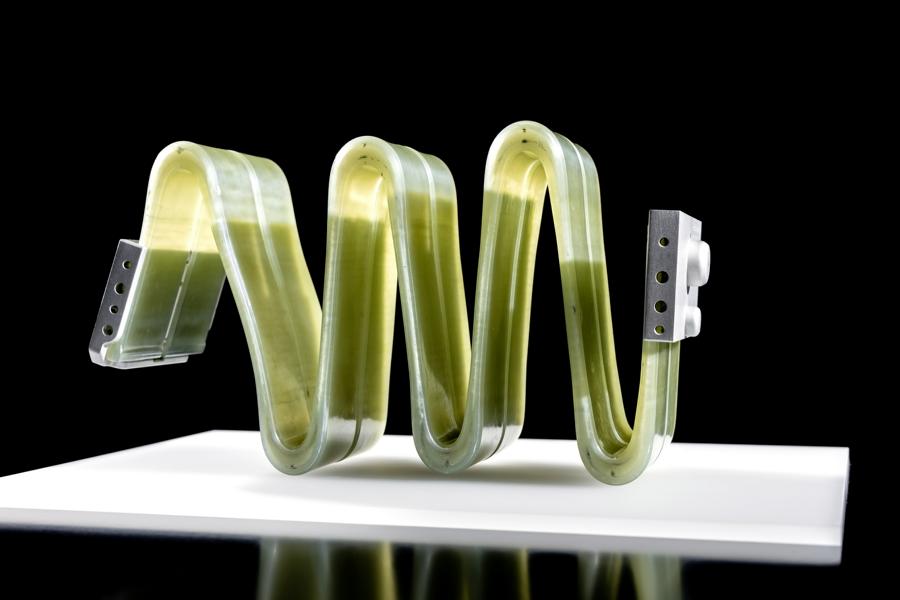

The lightweight concept was consistently implemented in the VISION EQXX. On the chassis, aluminum brake discs significantly reduce the unsprung mass compared to cast steel discs. The braking system developed by Mercedes-Benz Advanced Engineering has two other major advantages: It is completely corrosion-free, and it reduces brake dust emissions by up to 90 percent thanks to an innovative coating. New glass fiber reinforced plastic springs developed in cooperation with Rheinmetall Automotive have been developed, ensure further weight savings compared to conventional coil springs.

Neuromorphic computing - a car that thinks like the person who drives it

Another important efficiency feature of the VISION EQXX is its ability to think ahead. For system control, Mercedes-Benz uses a new type of information processing known as neuromorphic computing. So-called Spiking Neural Networks. These artificial neural networks imitate their natural counterparts in the human brain and only send signals when certain threshold values are reached. This significantly reduces energy consumption.

In collaboration with BrainChip - a Californian company that specializes in artificial intelligence - Mercedes-Benz engineers developed systems based on the Akida hardware and software from BrainChip. The example in the VISION EQXX is the hot word recognition “Hey Mercedes”. It is based on neuromorphic principles and is five to ten times more efficient than conventional voice control.

Although neuromorphic data processing is still in its infancy, experts assume that such systems will be available on the market in just a few years. Used on a large scale, they have the potential to radically reduce the energy required to run the latest AI technologies in vehicles.

UI / UX in the VISION EQXX - the unbiased travel companion

On a road trip, it is good if you are not traveling alone. A passenger helps with the navigation. Maybe he'll take care of the music selection too. Or he browses through the travel guide and points out interesting places and information along the way. Maybe he even gives one or two “tips” on driving style. In the VISION EQXX, all of this and more is done by the on-board computer so that the driver and front passenger can enjoy the journey in a relaxed manner.

The VISION EQXX demonstrates the potential of user interfaces based on a "game engine" with novel graphics and a highly adaptive design. The user interface shows how real-time graphics open up new digital worlds, react immediately to the needs of the driver and bring the real world into the car. The user experience in the VISION EQXX catapults us into an intelligent, software-controlled future. With an impressive design and intuitive operation, the first completely seamless display in a Mercedes-Benz extends over 47,5 inches from one A-pillar to the other. With an 8K resolution (7680 x 660 pixels), the thin and light mini-LED display functions as a portal that connects the driver and occupants with the car and the outside world. The tour guide is a “Star Cloud” avatar who is visually reminiscent of the brand's namesake, Mercedes Jellinek. It adapts to the needs of the driver, takes care of the passengers and makes the journey a luxurious experience. The system manages information to ensure that the driver gets exactly what he needs at the right time.

Together with the navigation expert NAVIS-Automotive Systems Inc. (NAVIS-AMS), the Mercedes-Benz team has developed the first real-time 3D navigation system for a screen of this size. It offers extensive zoom and scroll functions from the satellite view up to a height of ten meters in the 3D city display. It thus offers the user astonishingly clear, precise and intuitive route guidance.

Verbal communication is also fun with the road trip side kick in the VISION EQXX. The further development of the voice assistant “Hey Mercedes”, which was developed in collaboration with the voice synthesis experts from Sonantic, speaks expressively and emotionally. With the help of machine learning, “Hey Mercedes” has gained a distinctive character and personality. The emotional expression not only sounds convincingly real, but also elevates the conversation between driver and car to a whole new, more natural and intuitive level. This underlines the feeling of modern luxury conveyed by the UI / UX in the VISION EQXX.

Efficient use of energy and information

The one-piece display is also extremely energy-efficient. Its mini LED backlight consists of more than 3.000 local dimming zones. This means that electricity is only used in the areas of the screen where it is needed.

The 3D navigation screen adapts to the type of content displayed. For example, when the driver is driving in a city, the abstract visualization of the surrounding buildings helps with orientation in busy streets. However, when driving on the motorway or on the open road, the level of detail is reduced to give a better overview of the route. This further reduces the energy consumption of the display.

In addition to seamless navigation, the VISION EQXX can evaluate data based on the route. The avatar assists him as an intelligent travel guide. He can also help with the management of music files and make suitable suggestions for the respective location.

In addition, the VISION EQXX has a system that helps the driver to drive more efficiently. From the energy flow and battery status to the topography to the direction and intensity of wind and sun - the efficiency assistant collects all available information and thus generates recommendations for an energy-saving driving style. The driver's “horizon” is expanded because he receives information about external conditions that he cannot perceive directly. Just like a cyclist, for example, feels the strength of the wind or the extra effort when going uphill. This sensory support is supplemented by the ability of the VISION EQXX to “see into the future”, so to speak, with the help of the map data. In other words, to anticipate what is in store for the driver in order to help him drive efficiently. A spherical graphic in the display provides an intuitive overview, with sound if required.

And if the driver and passengers want more detailed information, they can find out everything that interests them on the screen - through easy-to-understand visual displays and infographics. The influence of current acceleration, incline, wind and rolling resistance on energy consumption is displayed in real time. If you want a comprehensive analysis, you get it. If you prefer to only find out what is absolutely necessary, the VISION EQXX shuts down the flow of information.

The interface is a further development of the zero-layer concept that was used for the first time in the EQS - and it is even easier to use. Because it facilitates the interaction between driver and vehicle by dispensing with submenus. Thanks to intelligence and personalization, the interface is particularly efficient and effective. It acts proactively and shows the driver what he needs when he needs it. An intuitive zoom function enables access to all functions. The front passenger has its own zoom function and its own entertainment area. And if you are traveling alone, you can switch off this part of the display to save energy.

Include sound in the equation

The operation of the sound system is also integrated in the VISION EQXX in the user interface. It combines an impressive 4D experience with exceptional energy efficiency. A conventional sound system can use a lot of energy. That is why Mercedes-Benz engineers have carefully examined how the sound experience can be optimized and energy consumption minimized at the same time. One way is to reduce the impact of sound waves that are either absorbed or reflected by interior surfaces.

By reducing the total number of speakers and placing them in close proximity to each occupant, the distance that sound travels significantly decreases. Two full-range speakers installed in each headrest are combined with a bass exciter in each seat. The VISION EQXX uses the exciter for normal audio playback as well as for vehicle noises, haptic feedback and acoustic warnings. The coupling of sound and haptic feedback is a very energy-efficient method to increase perception and awareness through more stimuli.

The design of the sound system in the VISION EQXX enables not only a reduction in energy consumption, but also several different sound zones. The efficiency assistant uses the sound system to communicate its recommendations to the driver via a series of intuitive audio signals - inspired by the tips commonly used in Formula E to help drivers drive more efficiently.

The development and testing process - a digital journey powered by software

The global road trip to electromobility is accelerated by advanced software and digital processes. There are a variety of main and secondary routes as well as inspiring highlights and milestones along the way. In order to generate as much relevant data as possible, the software management has gathered specialist knowledge and innovative ideas from all over the world - and thus created the basis for developing the VISION EQXX in the shortest possible time. The team used open source technology intensively for this, supplemented by internally developed elements. Agile working practices and monthly release planning ensured a continuous flow of end-to-end functions and the early integration of solutions.

The digital development work that went into the design and construction of the VISION EQXX is groundbreaking. State-of-the-art digital tools such as augmented and virtual reality made time-consuming physical models superfluous. They also enabled the simultaneous development work of remote teams working in different parts of the world - from Stuttgart in Germany to Bangalore, India, and from Brixworth in the UK to Sunnyvale, California. Thanks to this enormous digital performance, it was possible, for example, to reduce the time in the wind tunnel from more than 100 to just 46 hours. This also meant that more than 300.000 kilometers of test drives were covered virtually.

Software-in-the-loop (SiL) systems were also used extensively for digital validation. This made it possible to keep the commissioning phases extremely short with the real hardware. This made it possible to carry out large-scale tests at an early stage. Thanks to the consistent digitalization of the process, the team was able to install the drive unit, flash the software and put the VISION EQXX into operation within just two hours. This fast, efficient and responsive teamwork also benefited from experience in motorsport and the intelligent use of the extensive test options at Mercedes-Benz. Last but not least, the effective digital development approach enables many innovations from the VISION EQXX to be adapted quickly and precisely for series production.

DID YOU KNOW THAT THE EQXX VISION achieves more with less?

Being efficient means reducing waste to an absolute minimum in order to make the most of everything you have or need - energy, time or resources. In the Mercedes-Benz VISION EQXX, efficiency means: more range with less energy, more tangible luxury and comfort with less impact on nature and more electromobility with less waste. It also means radically shorter development times through the use of advanced digital tools and cross-functional teamwork.

... can travel from Berlin to Paris on a single load?

A single charge of the VISION EQXX can drive you from Berlin to Paris, from New York City to Cincinnati, Ohio, or from Beijing to Nanjing. Not because it has a large battery, but because it is highly efficient. Based on the average distance traveled per year, a driver in the USA or China would only have to fully charge the VISION EQXX twice a month and in Europe only once a month[14].

... is the electrical equivalent of a "1-liter car"?

The VISION EQXX consumes less than 10 kWh of electrical energy for a distance of 100 km[15]. This corresponds to a drive of six miles with one kWh of electrical energy. But what does that mean? Converted to the consumption of fossil fuels, this corresponds roughly to the value of one liter per 100 kilometers (235 mpg US or 282 mpg UK).

Some examples of what 10 kWh of energy mean in other areas of life:

- A tumble dryer runs a little over three hours.

- An average household air conditioner runs for around three hours.

- An iron can be used for about five hours.

- Watch TV for 100 hours on a 50-inch LED device.

- Around three minutes of operation of a conventional (non-LED) floodlight system in a large sports stadium.

... is more aerodynamic than American football?

On a long-distance journey, a typical electric car uses around two thirds of its energy to move through the air. With 0,17[16] can the groundbreaking cwValue of the VISION EQXX can make a big difference at motorway speeds. A reduction of just 0,01 increases the range by around 2,5 percent.

Comparison with some other drag coefficients:

Penguin: 0,05

VISION EQXX: 0,1716

EQS: 0,20

American football: 0,18 to 0,2

Cyclists: 0,6 to> 0,8

Person: 0,8 to 1,2

Parachute: 1,1 to 1,3

Don't worry, of course that was far from being the case when it came to auto / auto tuning. Our magazine still has tens of thousands other tuning reports in stock. Do you want to see them all? Then just click HERE and look around. Or are you particularly interested in everything to do with vehicles from the brand Mercedes-Benz? Then the following excerpt is for sure just the right thing.

VISION EQXX - electric range and efficiency on a completely new level

Photo credit: Mercedes-Benz

tuningblog.eu - on the subject of cars, motorcycles, bikes / ATV / scooters & Co., and of course our passion, the Tuning, we keep you up to date and report daily on cool vehicles from all over the world. It's best to subscribe to ours Feed and you will be automatically informed as soon as there is a new post.

tuningblog.eu Your magazine about tuning the car

tuningblog.eu Your magazine about tuning the car