Step on the gas again? Patented technology enables combustion engines to be retrofitted to run on LPG and promises emissions reductions of up to 95 percent! The drive technology is suitable for many vehicle classes as well as trucks, buses, agricultural and construction machinery and ships. Road approval is currently being worked on in Switzerland. On 01.01.2035/XNUMX/XNUMX is due date: From then on, vehicles with combustion engines that produce CO₂ emissions may no longer be registered in the EU. There are only a few exceptions, for example in the case of eFuels. This decision is intended to force the member states to force the switch to e-mobility or to use alternative energy sources such as hydrogen in engines. From an economic point of view, however, these technologies are often not mature enough to enable ranges that are comparable to conventional vehicles. In addition, there is a lack of a nationwide charging infrastructure and a guarantee for price-stable "green" electricity, which has made potential buyers hesitant so far. This is most likely not a short-term solution for the turn to green mobility.

Technology enables retrofitting

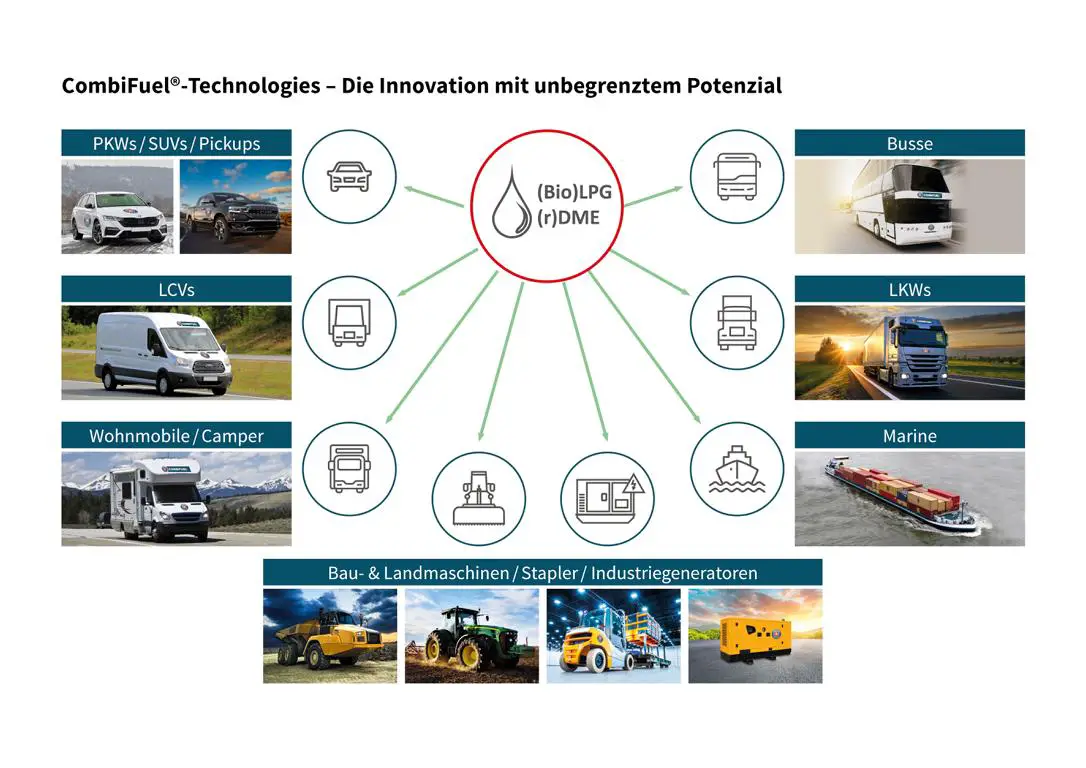

However, this gap can be closed with an innovation from Switzerland: CombiFuel Swiss AG offers a technology that has been tested and certified on numerous types of vehicle, which already today makes it possible to convert conventional combustion engines (petrol or diesel) to lower-emission and therefore more environmentally friendly liquid gas (autogas /LPG) to retrofit. With this alone, a considerable amount of pollutant emissions could be significantly reduced. The new drive system currently uses fossil liquefied gas, but in future also BioLPG and dimethyl ether (rDME) and can be adapted to new types of synthetic fuels. The plug-in technology has been developed in such a way that, in addition to passenger car applications, it is also suitable for engines in buses, trucks, construction machinery, ships and even industrial generators. Independent tests have shown that, depending on the engine, fuel and route, up to 95 percent of selected emission types can be reduced and – depending on the price level per country – up to 50 percent in fuel costs can be saved at the same time.

In order to drastically reduce global CO2 emissions and to promote the mobility revolution, the EU recently decided to ban the new registration of combustion vehicles with a poor emissions balance from 2035. In addition, various vehicle manufacturers have been testing and developing alternative drive variants for some time, which are less prone to emissions and are based on regenerative energies. However, electric motors, hydrogen tanks and hybrid variants are united by the fact that insufficient storage capacities and a lack of charging infrastructure currently still limit the range of such vehicles comparatively. In addition, some systems are more sensitive due to the fuel used - hydrogen e.g. B. works with pressure values of 350 to 700 bar - so that the tank and safety technology on the vehicle is more complex and the technology is currently not very profitable.

Future-oriented technology offers short and medium-term solution

"There is no right or wrong when it comes to alternative drive technologies," explains Eckhard Tilhof, Chairman of the Board of Directors of CombiFuel Swiss AG. "Because every approach that demonstrably reduces the emission of climate-damaging exhaust gases is good." The use of CombiFuel® technology and other bridging technologies thus plays a decisive role in reducing the amount of emissions in the short and medium term, while manufacturers and research continue to be able to work with a reliable energy and drive mix.

That is why CombiFuel relies on a future-oriented technology with which new and existing vehicles as well as passenger and commercial vehicles can be retrofitted immediately and permanently to lower and thus more climate-friendly emission values. Liquefied petroleum gas (LPG/Autogas) is used as the basic fuel and substitute for petrol or diesel. Since more and more countries are banning the burning off of liquid gas during the production of natural gas and oil, using it as a fuel offers a good alternative. Another advantage of the comparatively future-proof energy source: Germany already has a well-developed infrastructure for refueling with liquid gas. Roughly every second petrol station in Germany offers LPG. In addition, unlike hydrogen or electricity, it can be transported and stored flexibly, which makes the fuel particularly attractive for use in rural areas. The synthetically produced rDME (renewable dimethyl ether) is also suitable as a fuel, as it behaves similarly to LPG and is produced in sufficient quantities as a process gas in many industries.

Smart conversion instead of buying a new car

Switching to LPG is not difficult: CombiFuel® technology is a plug-in solution that is attached to the engine using a cable harness that we developed ourselves. An adaptive control unit specially designed by the company, which is compatible with modern vehicle diagnostic systems (OBD), then switches between the engine, tank and vehicle electronics. "Basically, the smart component 'takes over' control of the engine and enables the vehicle to use LPG or, in the future, rDME as a fuel in addition to petrol or diesel," says Tilhof, describing the principle. Larger conversions such as replacing the motor units are therefore not necessary. A special sensor, which is unique in this form, ensures optimal ignition as well as fuel and power efficiency: This recognizes the liquid gas mixture ratio of e.g. propane and butane and reports the information to the control unit so that it can carry out the optimal engine control. A special evaporator/pressure regulator ensures engine performance of up to 750 hp - or over 1.000 hp in the next stage of expansion - so that the upgrade has no effect on driving behavior.

To ensure that all components are ready for series production, they were subjected to aging, acid, resistance, pressure and temperature tests at an EU-accredited laboratory in the Netherlands. Since 2022, all components of the CombiFuel system have been certified according to the very strict UN standard UN ECE R 67. The set of rules defines the requirements for an LPG system that is to be installed in a vehicle and for its equipment. In addition, CombiFuel Swiss AG has already retrofitted various vehicle types as prototypes that are currently in the approval process. These have already been tested over hundreds of thousands of kilometers. For example, a converted Opel Astra (prototype with 45.000 km) emitted 28 percent less carbon dioxide, 83 percent less carbon monoxide and 96 percent less nitrogen oxides per kilometer on a certified test bench at Fakt in Memmingen (Germany) than in regular diesel operation.

Technology compatible with most conventional internal combustion engines

"In order to achieve the greatest effect over the area and thus the greatest possible savings in terms of emissions, our goal is to convert as many vehicle classes as possible," says Tilhof, giving an outlook. That is why the company works closely with various test laboratories, the relevant authorities and vehicle fleet operators. “The homologation for road traffic is always based on an engine family. As a result, CombiFuel® can be used with approval in all vehicles with the appropriate engine and the appropriate gear ratio, with or without individual approval,” says Tilhof. CombiFuel® is primarily aimed at the commercial sector, e.g. fleet vehicles, trucks from haulage companies, buses, agricultural and construction vehicles, and represents an immediately usable alternative to fuel-efficient and emission-intensive petrol or diesel drives. The technology is therefore suitable for both long distances and has been optimized for the high performance requirements of commercial vehicles (e.g. transport and agricultural vehicles) under full load and is therefore ideally suited for this.

Of course, that wasn't the end of it!

tuningblog has countless other articles on the subject of car and auto tuning in stock. Do you want to see them all? Just click HERE and look around. In part, we would like to provide you with news but also off the tuning. In our category Tips, products, information & Co We have reviews of car or accessories manufacturers, new ones Tuning Wiki Terms or one or the other Leak veröffentlicht. Just click on one of the following posts!

tuningblog.eu Your magazine about tuning the car

tuningblog.eu Your magazine about tuning the car