Recently updated on March 9, 2023 at 10:04 am

Hinges are used to move the doors in various systems from home to car doors. They allow all types of swing doors to be opened and closed. In general, the hinges are either welded or attached to the frame of the respective system with a nut and bolt system. This connection is permanent and can subsequently only be separated again with great effort.

Car door hinges are essential components of the door support system that connects the door to the vehicle body. Its task is, on the one hand, to hold the door in its exact position despite all everyday stresses, in order to enable trouble-free entry and exit over the long term. On the other hand, they have to keep them within limits in the event of a side impact or rollover. In other words, being able to withstand strong forces.

Hinge solutions in the automotive industry

During the research and development phase of an automotive door hinge, a number of testing and approval processes take place to ensure its reliability. Depending on the requirements of the manufacturer (OEM), different types of functional tests can be carried out.

For example, in one of these, when the car door is opened to the maximum, a certain force is exerted on the newly developed door hinge. If it can withstand this, the design is considered ready for series production. If the result is the opposite, further optimization must be carried out. A car door hinge system consists of two hinges for each door, one upper and one lower. Conventional models consist of four parts:

- A fixed part on the vehicle body,

- a moving part on the door,

- a bolt to connect the fixed and moving components

- and a plastic stopper to reduce the noise when opening and closing the door.

Traditionally, these components are made of mild steel using the forging process. More recently, however, lightweight design concepts have come to the fore in the automotive industry, especially with regard to economic and ecological sustainability.

The use of lighter materials should reduce fuel consumption and, as a result, the environmental impact. Among these materials, aluminum alloys stand out, which have excellent mechanical properties and high specific strength.

Different types of hinges in vehicle construction

Based on this basic system, there are various hinge solutions in the automotive industry, which we would like to present to you in more detail below.

Hinges for concealed installation

As a rule, hinges in car doors are concealed. A concealed hinge is one that sits flush with the door, thus concealing its position. The purpose of the concealed (or invisible) hinge is to provide an aesthetically pleasing and consistent appearance.

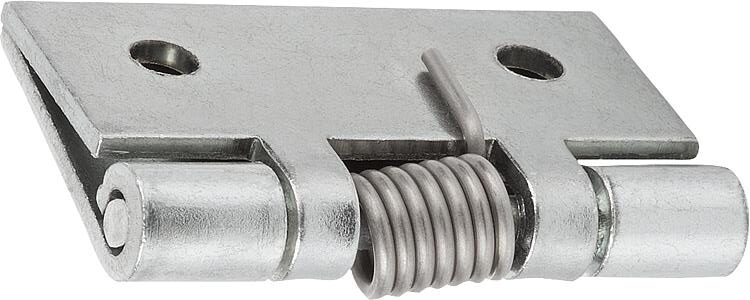

Spring hinges

A spring hinge (also known as a self-closing hinge or door closer hinge) is a hinge equipped with a spring that automatically closes the door from an open position. There are single sprung and double sprung models.

The closing force of the spring mechanism can be adjusted, making the door close slower or faster. How much tension is needed depends on the weight of the door and the desired closing speed. On car doors, a spring hinge typically latches in the widest open position and must be manually released before closing.

torque hinges

Torque hinges (also called friction hinges) offer resistance to the rotational movement of the hinge itself, making them suitable for holding a lid, door, bezel, or display device at a certain angle for an extended period of time. Friction hinges can maintain their position even when a force is applied to them. They are therefore also referred to as free-stop hinges. The resistance responsible for this property results from frictional forces that are built up inside the hinge. Different mechanisms are used to generate friction, which is why there are different types of torque hinges. The most important are the disk, roller, question mark and conical types. In addition, we at Reell have developed our own patented solution as a fifth option.

This type of hinge has found acceptance in the automotive industry as well as in a variety of commercial and industrial applications due to its high level of practicality and durability at the same time. Depending on the type, format and components used, there are large differences in the load capacity between the different models of torque hinges. In addition, most of these show some variability. In other words, they stop within a certain range and not at a certain point. That is why you will almost always find a ± symbol next to the relevant manufacturer information.

However, this is not unique to each manufacturer, but rather an unavoidable side effect of the torque hinge manufacturing process. Because of this, it is important to accurately calculate each application area to ensure that the hinge will function properly despite these variations.

To that end, it is important to choose a model that is above but close to the lower limit. If it is below this, there is no guarantee that the hinge will hold the door or hatch in the intended position. If it is too much above the lower limit, the moving part will become very rigid and difficult to move. Depending on the design and functional principle, there are different types of torque hinges.

Hinges with one-sided torque

One-way torque hinges have friction that only works in one direction. This feature facilitates opening and lifting while maintaining the free stop function. A simple solution for not too demanding applications.

Hinges with adjustable torque

Adjustable torque hinges allow the torque applied to the hinge to be adjusted. This can be very useful when fine-tuning torque hinges to make the operating feel as comfortable as possible. The weak point of this type of hinge, however, is that it loses strength relatively quickly due to material fatigue, which makes it unsuitable for areas with high stress.

Locking Hinges (Lockable Torque Hinge)

Locking hinges can be locked in various predetermined positions and thus ensure that doors or flaps remain securely open. Depending on the model, the hinge with lock has a different number of predefined notches. Also dependent on the respective model is the torque that is required to overcome the latching point of the hinge and thus release the lock again. The disadvantage of lockable friction hinges is of course that they can only be locked at the specified angles.

Hinges with stepless holding function

Such a hinge consists of a bearing part that carries a non-rotatable bearing pin. As well as a hinge part pivoted on the bearing pin, the pivoting movement of which is controlled by a bracket integrated in the pivot bearing of the hinge part. This serves as a roller bearing between the bearing pin and the hinge part. The roller bearing, in turn, usually has an adjustable preload. This predetermined holding force enables it to be fixed in any pivoting position. This makes this type of hinge superior to the previously mentioned variants.

That's why we at Reell only use torque hinges with an infinitely variable holding function. The patented ReellTorq® clip technology not only ensures smooth, precise handling, but is also practically wear-free. Our high-precision friction hinges are available in numerous sizes and designs with a maximum load capacity of up to 11,30 Nm. If you have any questions about our innovative hinge solutions for the automotive industry, please contact us today. We are looking forward to your message.

Of course, that wasn't the end of it!

tuningblog has countless other articles on the subject of car and auto tuning in stock. Do you want to see them all? Just click HERE and look around. In part, we would like to provide you with news but also off the tuning. In our category Tips, products, information & Co We have reviews of car or accessories manufacturers, new ones Tuning Wiki Terms or one or the other Leak veröffentlicht. Just click on one of the following posts!

tuningblog.eu Your magazine about tuning the car

tuningblog.eu Your magazine about tuning the car