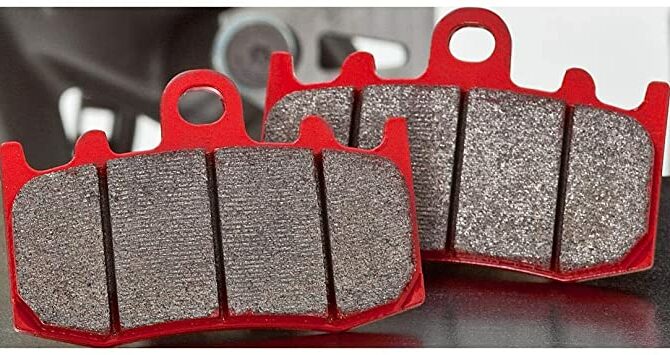

The pad cake is with particularly high-quality brake pads sintered, since this is exposed to a high load. At the sintering are under pressure and heat fifteen different metals in powder form compacted. The special manufacturing process connects the metal and enables a very high level of strength. The sintered coverings are almost there inseparable connected with each other. The topping cake merges with the carrier plate in this special production due to the high temperatures of up to 1.000 degrees Celsius. That is the crucial difference to the glued topping cake of organic coverings.

Advantages - brake pads with sintered metal

- An higher and more constant Coefficient of friction independent of the temperature.

- Extrem high resistance in temperature.

- No combustible abrasion the brake pads.

- An much longer service life compared to organic coverings.

So which brake pads should I use? Sintered or Organic?

Sintered brake pads are harder and more resistant in the heat as organic brake pads. The reason is that when "sintering" the fine-grained metals and ceramic parts with a lot of heat and pressure fused together become. In comparison, organic brake pads mix over twenty different carbons from organic chemistry. This is how the name "organic brake pad" conditions. Organic brake pads are also called Disc brake pads designated. The substances are mixed with a synthetic resin as a base mixed and pressed.

Advantages and disadvantages of sintered brake pads:

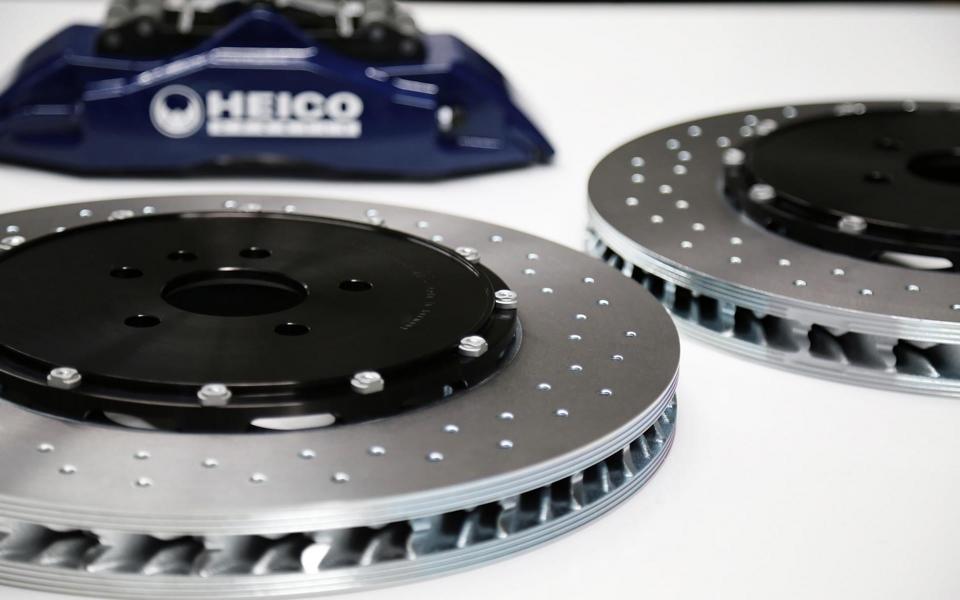

With sintered brake linings, the brakes generate more heat. The brake pads are harder and have better resistance to heat. However, it is also a stronger squeak possible when braking. There are also sintered brake pads only suitable for well-ventilated and large brake discs.

Advantages and disadvantages of organic brake pads

Organic brake pads are a lot soft and can also for smaller brake discs be used. In addition, there is a lower or when braking no squeak. However, these rubbers have a worse resistance against heat and have a higher level of wear and tear.

The right composition of the material is therefore crucial when choosing coverings. Especially with vintage cars there are different types of coverings available. It does no difference, whether disc or drum brakes are built in. Depending on the intended use, there are therefore numerous advantages and disadvantages with the brake pads.

Composition - organic coverings

Organic brake pads are made up of modified fibers Vegetable fibers, glass, carbon, kevlar or Rubber, produced. Be there natural or artificial resins used as a filler. The organic toppings however, use up quickly ab, but are considered quietest Pad type and there is hardly any wear on the brake discs. These types of rubbers are more suitable for cruisers and not suitable for use on the racetrack. The reason for this is that organic brake pads cause a worse coefficient of friction and the properties against heat are relatively poor.

Composition - sintered metal coverings

The sintered brake pads are made with filler as well Graphite mixed and instruct Metal content of 30-65% on. However, with these linings, the wear on the brake discs is relatively high and, due to the metal content, they tend to squeak heavily. However, this type has good braking properties and the braking force is at high temperature hoch. However, caution is advised at low temperatures because the poor braking properties are by no means to be underestimated. Therefore, these brake pads need be warmed upso that a good coefficient of friction is ensured. The brake pads are primarily for use on the racetrack suitable. Due to the squeaking noises and the poor coefficient of cold friction, they are not really suitable for everyday use.

Low-metallic coverings as a solution?

These types of brake pads make a good one Alternatives to the above coverings. They unite good properties in heat and lower volume together. With these brake pads is the Metal content at 10% to 30%. Therefore, this type of pad is in great demand on current vehicles such as the Ford Mustang models. In particular, there are HAWK HPS and HAWK HP Plus coverings with different metal components.

Ceramic coverings as an alternative?

This type of brake pad is special quiet and leaves the brake discs little wear and tear. And the ceramic brake pads have similar properties to the sintered metal pads. However, ceramic brake pads are rarely found on the market. Regardless of the designation is a low percentage contained in metal. The HAWK PC type is an example of ceramic coverings.

PS: all brake pads available on the market in the EU must be certified according to the ECE-R90 standard.

We hope that you have received our information report on the topic / term Sintered metal brake pads (further designations / keywords are: lining cake, ceramic linings, ceramic linings, ceramic brake linings, sintered brake linings, ceramic linings, ceramic brake linings, disc brake linings, ceramic linings, ceramic brake linings, ceramic linings, ceramic brake linings, organic linings, organic brake linings, sintered metal linings, sintered metal brake linings, Sintered metal pads, sintered metal brake pads, sintered metal brake pads, semi-metallic brake pads, non-asbestos organic brake pads, NAO brake pads, sintering, low-metallic pads, low-metallic brake pads) from the Autotuning category. Our goal is to have the largest German-speaking tuning lexicon (Tuning Wikipedia) and to explain tuning technical terms from A to Z easily and understandably. We are therefore expanding this lexicon almost daily and you can see how far we have already come HERE see. And soon the next one will be Tuning scene concept illuminated by us. There's a theme that not can be found in our Wikipedia? Then send us an email at kontakt@tuningblog.eu and gives us the term. We will write a suitable article as soon as possible. PS. By the way, you will be informed about new topics if you have ours Feed subscriber.

Below are a few examples from our tuning lexicon:

But of course tuningblog has countless other articles on the subject of cars & car tuning in stock. Do you want to see them all? Just click HERE and look around. We would also like to provide you with news aside from the tuning. In our category Tips, products, information & Co we pick up contributions from car or accessory manufacturers. And also our category Test sites, laws, offenses, information has almost daily new information for you. Here are a few topics from our tuning wiki:

"Tuningblog.eu" - we keep you up to date on the subject of car tuning and car styling with our tuning magazine and we present you the latest tuned vehicles from all over the world every day. It's best to subscribe to ours Feed and will automatically be informed as soon as there is something new about this post, and of course also to all other contributions.

tuningblog.eu Your magazine about tuning the car

tuningblog.eu Your magazine about tuning the car