Recently updated on January 30, 2020 at 06:22 am

Automotive components can be made more durable and even more visually appealing using various techniques. In general, the processes are called Refining designated. One particular technique that is considered surface finishing and is also used in auto tuning is galvanization. Exactly what electroplating is and what it is used for in auto tuning is explained below.

Electroplating - what is it?

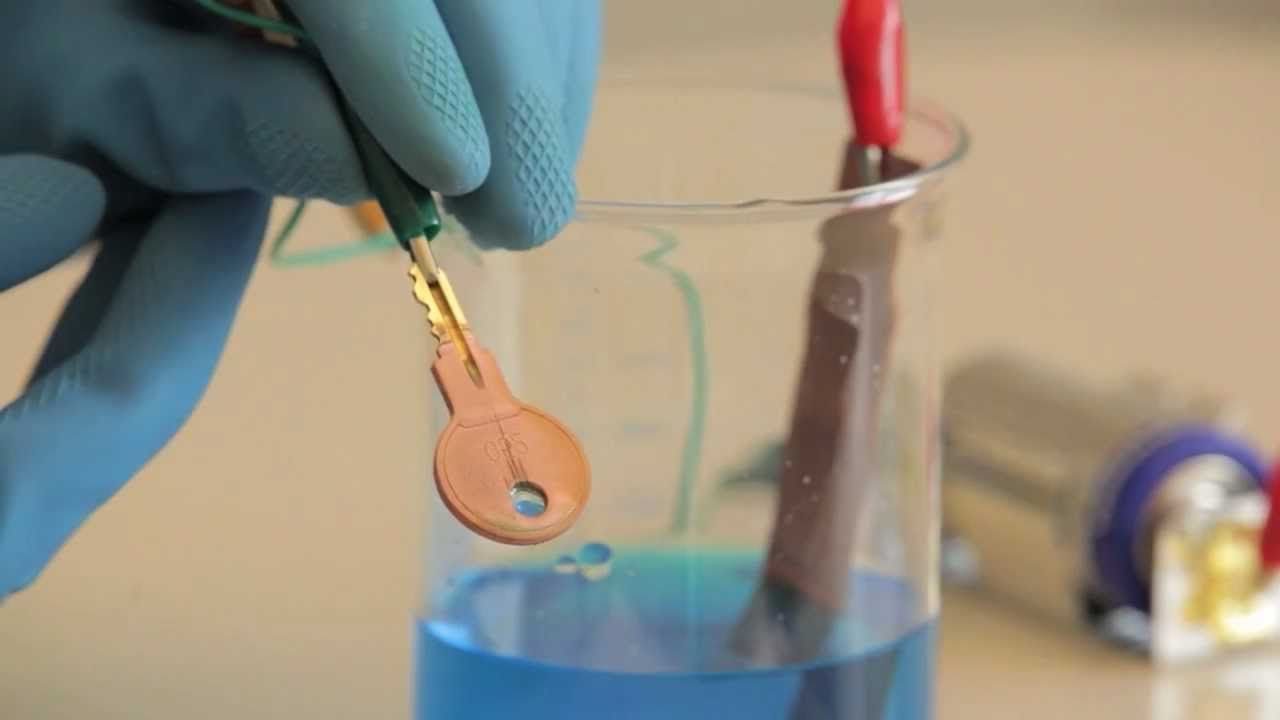

Electroplating describes a technical process in which objects are coated with metallic deposits. The coating is possible by electrochemical deposition. Precious metals or base metals can be used in the electroplating. In addition to the galvanization of metals, plastics and non-conductors can also be coated. Precious metals that are used for electroplating are, for example, silver, brass, Copper, Gold or Chromium, If non-conductive automotive parts are galvanized, they must first be made electrically conductive. Graphite is usually used for this. There are various methods for electroplating plastics. The Futuron process is common, for example. This process involves direct metallization.

What is galvanization for?

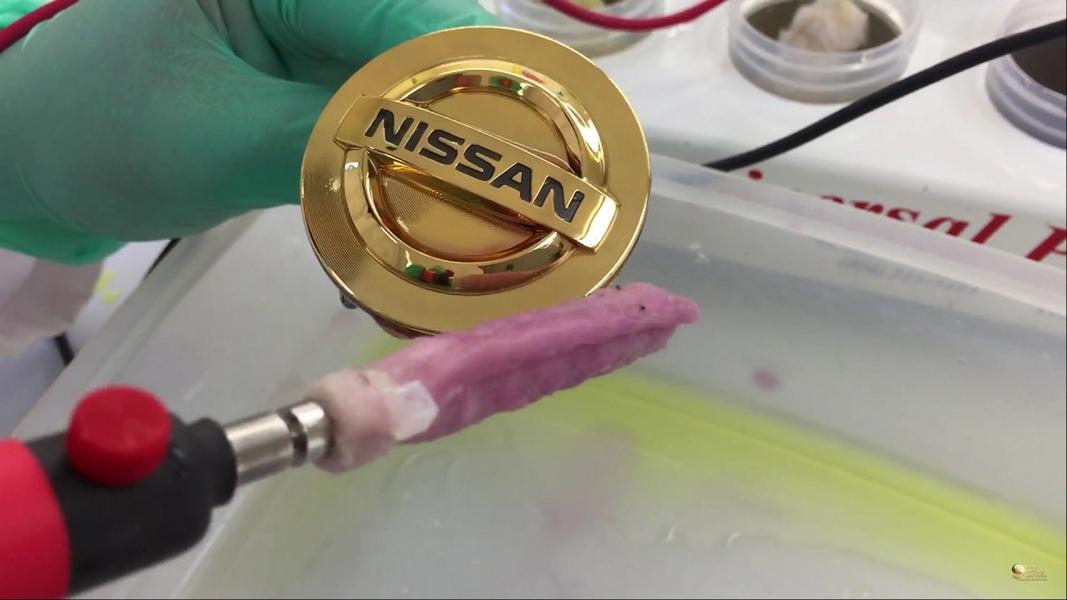

For example, rims and screws for the automotive sector are electroplated. Other automotive parts that are used, for example, for classic car restoration are also galvanized. Electroplating is carried out to protect the objects from corrosion and wear. The finishing is also used to reduce friction, for example in plain bearings. Another reason for the galvanization of automotive parts is the decorative look. Surfaces can be visually upgraded significantly through the refinement.

Galvanization for classic car components

The galvanization is used for example for classic car components. Certain specialist workshops that specialize in the restoration of classic cars use the galvanization method. The refinement of various components makes the classic car an eye-catcher. Anyone who commissions a workshop to restore their classic car should definitely use an experienced specialist workshop. The specialist workshops usually have expertise to offer and show on the homepage already completed projects on which they have worked. The refinement by electroplating has to be optimal so that the classic car or the vehicle component lasts long and looks good in the long term. If individual components are galvanized, the raw part must be well prepared for the process. Nothing is worse than if after a short time the treated and refined components begin to dissolve and, for example, the applied chrome layer crumbles off.

Preparation for finishing

Electroplating is carried out on grease, paint and paint-free components. The surfaces of the components are optimally and optimally freed of dirt so that the applied material adheres optimally. If present, old metal layers must be removed. Rust as well as dents and corrosion scars must also be removed or repaired. If a motor vehicle part consists of several components, then it must be broken down into its individual components. Not all metals can be processed together. In addition to the actual electroplating process, further finishing processes can then be carried out. This is advantageous, for example, if a component is to have a particularly shiny finish or if it should have other optical advantages. If you want to have automotive components refined, you should ask a specialist workshop specializing in this process. Appropriate specialist workshops can be found on the Internet. Regardless of whether gilding the rims, galvanizing and refining the emblem of the car or bringing elements in the interior to a high gloss. Everything is possible!

We hope that you the info report on the topic / term Electroplate (further names / keywords: Strip electroplating, burnishing, chemical nickel, chromating, direct metallizing, electrodeposition, electroplating, coloring of metal, electroplating, electroplating, Yellow galvanizing, Plastic plating, metallization, phosphating, polymer coating, brewing process, pad plating, dipping process, drum plating, galvanizing, blasting) from the field of autotuning. Our goal is that the largest German-language tuning dictionary (Tuning Wikipedia) and to explain tuning terms from A to Z easily and understandably. Almost every day we expand this lexicon and how far we are, you can HERE see. Soon the next one will be Tuning scene concept be illuminated by us. By the way, you will be informed about new topics if you have ours Feed subscribe to.

Below are a few examples from our tuning lexicon:

But of course tuningblog has countless other articles on the subject of cars & car tuning in stock. Do you want to see them all? Just click HERE and look around. We would also like to provide you with news aside from the tuning. In our category Tips, products, information & Co we pick up contributions from car or accessory manufacturers. And also our category Test sites, laws, offenses, information has almost daily new information for you. Here are a few topics from our tuning wiki:

|

Artificial leather - the perfect alternative for car tuning! |

"Tuningblog.eu" - we keep you up to date on the subject of car tuning and car styling with our tuning magazine and we present you the latest tuned vehicles from all over the world every day. It's best to subscribe to ours Feed and will automatically be informed as soon as there is something new about this post, and of course also to all other contributions.

tuningblog.eu Your magazine about tuning the car

tuningblog.eu Your magazine about tuning the car

Thank you for this post on electroplating. It is good to know that this technology is often used on old-timer parts. I am considering buying a classic car and therefore find out how best to protect the car parts. I also found further information here: