Before you consider replacing your clutch with a Sport clutch or even a thoroughbred Sintered metal coupling You should first find out which clutch is the right one for your car. If you need support with this question, it is best to contact a specialist advisor or at least find out more in advance on the Internet and have the information on the vehicle manufacturer, the vehicle type and the engine or chassis number ready. Any tuning measures that have already been carried out are of course also important.

The right covering is crucial!

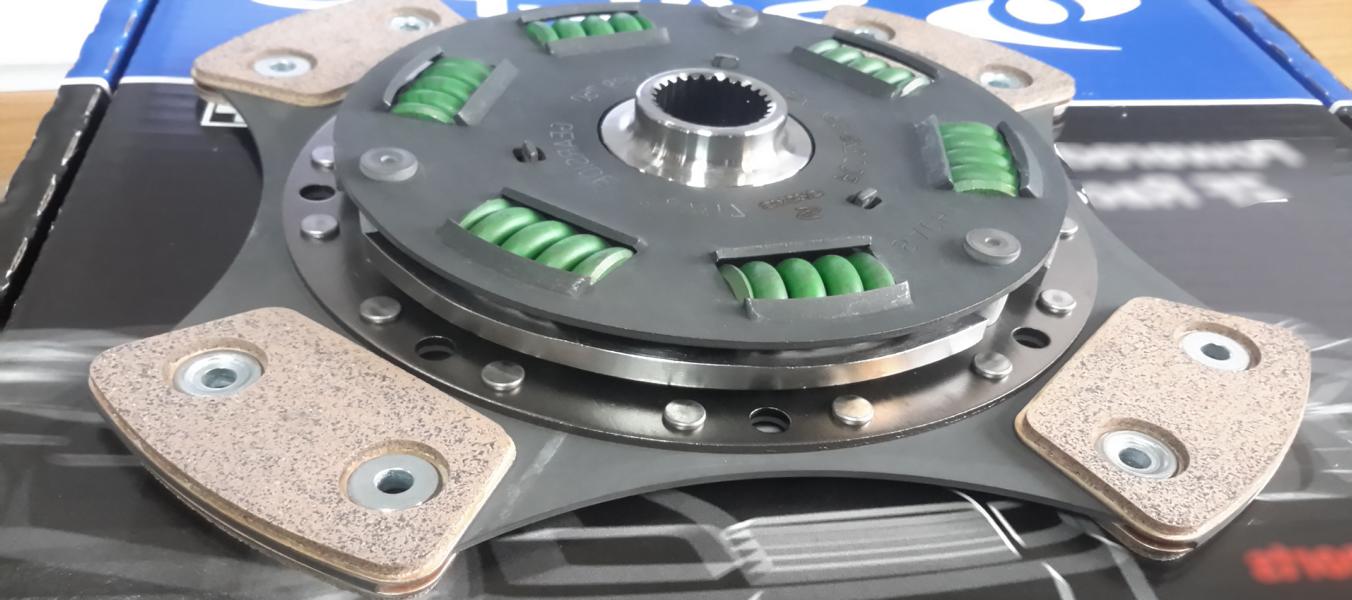

As you may know, a coupling consists of one, among other things printing plate and an Clutch disc. The clutch disc differs depending on the nature of the lining.

- Organic coupling

In an organic coupling there is a organic topping on the entire circular surface of the drive plate. This separates or closes the clutch extremely smoothly and withstands normal temperatures. Temporarily the covering can also withstand higher temperatures. For this reason, an organic coating is particularly suitable for clutch disks with a relative large diameter, as well as for vehicles with normal Torque.

- Sintered metal coupling

The sintered metal coupling consists of one ceramic-metallic covering, which is also called Sintered metal covering referred to as. This topping enables the transfer of a higher torque with significantly lower contact pressure. In addition, it can normally withstand higher temperatures. The sintered metal coating has a higher weight and the resulting high inertia can lead to a faster closure guide on the flywheel and the pressure plate. However, the covering itself is extremely robust and wear-resistant. The surface is therefore suitable for particularly powerful vehicles.

Properties of the sintered metal coupling

- The more friction disks, the more Engine moment can transmit the clutch

- The more friction disks, the more Temperature can accommodate the clutch

- Sintered metal clutches often have a "short" grinding point and engage more aggressively

- Sintered metal clutches are less than conventional sports clutches (e.g. from Sachs) everyday use

- Sintered metal clutches are particularly suitable for vehicles for the racetrack

- there are no slipping the clutch, regardless of the speed

- Sintered metal disks, like series disks, can be torsion-sprung or they are completely rigid

- Torsion-sprung variants can often also be used in road traffic

- Rigid sintered metal disks cannot be used in the city

The two parts of a clutch that make contact, i.e. the drive plate and the flywheel or the dual-mass flywheel (DMF), are matched to one another in terms of their material. If a sintered metal coupling (what is meant is almost always only the drive plate), the original material pairing is no longer available. As a result, the flywheel wears out faster. The principle also applies to the Bremsanlage. Will only those Brake pads by sintered metal pads replaced, the discs wear out faster.

Leave coupling replacement to the professionals

Removal of the old coupling: After removing the coupling, a few points should be checked.

- On the one hand, it should flywheel be checked for sanding belts and a bump-free contact surface, as well as for cracks or blue discolouration. If necessary, the flywheel must be replaced immediately.

- In addition, the transmission should also be on his Tightness checked and sealing rings replaced if necessary.

- Finally, the transmission input shaft and the pilot bearing should also be checked and replaced if necessary.

And finally ... Sintered clutch is a term that actually only refers to the drive plate from the clutch kit. In contrast to the standard drive plate, in the sintered version the organic friction lining is replaced by individual pads made of sintered metal. This achieves a higher coefficient of friction and a higher temperature resistance. While the coefficient of friction of organic series linings is around 0,25, it increases to around 0,30 with glued racing linings (organic). In the case of sintered metal, ceram (ceramic), carbon fiber or carbon, the coefficients of friction are in the range of 0,4 or even higher. And the heat development in the clutch even improves the friction effect. With the same load, a series-produced lining decreases significantly in terms of the friction effect or even burns.

We hope that you have received our information report on the topic / term Sintered metal coupling (Further designations / keywords are: sintered metal coupling, sintered coupling, sintered coupling) from the Autotuning category. Our goal is to have the largest German-speaking tuning lexicon (Tuning Wikipedia) and to explain tuning technical terms from A to Z easily and understandably. We are therefore expanding this lexicon almost daily and you can see how far we have already come HERE see. And soon the next one will be Tuning scene concept illuminated by us. There's a theme that not can be found in our Wikipedia? Then send us an email at kontakt@tuningblog.eu and gives us the term. We will write a suitable article as soon as possible. PS. By the way, you will be informed about new topics if you have ours Feed subscriber.

Below are a few examples from our tuning lexicon:

But of course tuningblog has countless other articles on the subject of cars & car tuning in stock. Do you want to see them all? Just click HERE and look around. We would also like to provide you with news aside from the tuning. In our category Tips, products, information & Co we pick up contributions from car or accessory manufacturers. And also our category Test sites, laws, offenses, information has almost daily new information for you. Here are a few topics from our tuning wiki:

|

Sintered metal, ceramic, low-metallic |

"Tuningblog.eu" - we keep you up to date on the subject of car tuning and car styling with our tuning magazine and we present you the latest tuned vehicles from all over the world every day. It's best to subscribe to ours Feed and will automatically be informed as soon as there is something new about this post, and of course also to all other contributions.

tuningblog.eu Your magazine about tuning the car

tuningblog.eu Your magazine about tuning the car