Recently updated on January 27, 2022 at 10:36 am

Why do you actually have to reset the so-called control times on the engine? The timing of the camshaft changes over time, because the timing chain increases by a few millimeters over the years or it had to be replaced due to a defect. Through this so-called elongation, the filling torque of the vehicle's cylinder is changed and the ignition point is influenced in such a way that the engine performance decreases. Frequent starting processes, driving short distances and the kilometers driven lengthen the timing chain. A certain elongation can still be absorbed by installing different disc springs. There are 4 correction levels for this. If these are exhausted, the timing chain must be replaced. There is not necessarily any audible indication of this. The engine performance gradually decreases, so that you hardly notice it at first - you only notice the problem when it is hardly possible to compensate and the new timing chain is needed. It is important to do a visual inspection and then a measurement of the timing chain.

Brief description for a Mercedes-Benz M116 / M117 engine:

In this article you can read how the camshaft timing is checked and set on the M116 / M117 engine.

- Preparation:

- Stand the hood upright.

- Remove the ignition cable with the distributor cap.

- Remove the cylinder head cover on both sides (3 Nm).

- Remove the KPR.

- Remove the spark plugs.

- Only partially draining the cooling water.

- Disconnect the upper radiator hose and the radiator.

- Remove the fan shroud.

- Remove the fan (4 screws SW10 / 15 Nm).

- Read the check number / code number of the camshaft at its rear end. (Make a note or remember this). - Visual inspection:

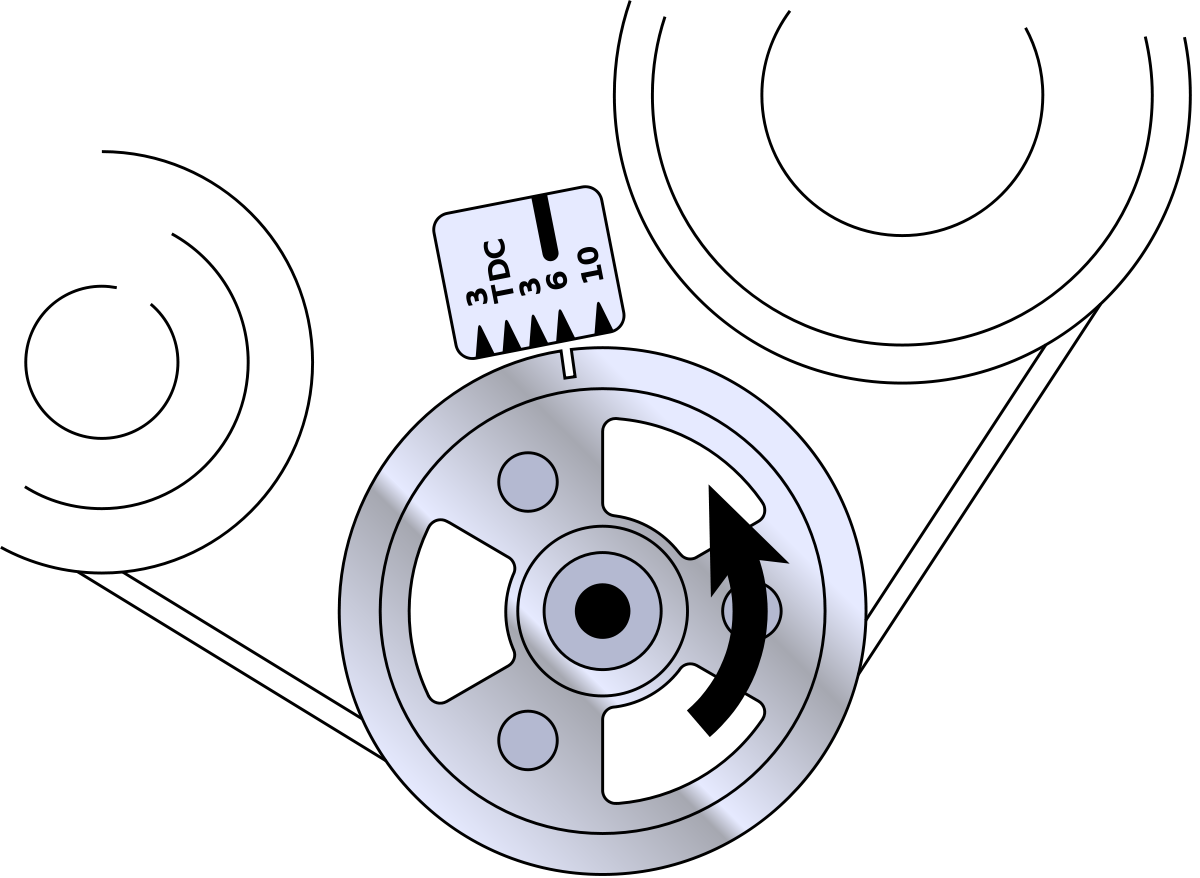

- Before measuring, you should first make a visual inspection. It's easy and quick. All you have to do is turn the engine clockwise by hand so that the notch and the marking on the camshaft are aligned on the left. Then check the right cylinder bank to see how the markings are there. If the deviation is greater there, action is required. If there is a smaller deviation or if there is no deviation, the motor can be closed again!

So that a different offset of the camshafts can be determined, take the measurement as follows:

- Turn the engine clockwise by hand until the pointer of the flywheel on the crankshaft is on "0".

- The distributor finger on the distributor (remove the cap) points to the 1st cylinder.

- Check the alignment of the markings on the two camshafts; if there is a difference in markings, it is assumed that different disc springs are used. If the right bank is slightly offset, only the right side needs to be readjusted.

- Check:

- The test is carried out on the inlet valve of the first cylinder of the right cylinder bank and the sixth cylinder of the left cylinder bank. To do this, first the rocker arm and then the hydro element are removed.

- Then turn the engine clockwise by hand until the cam of the camshaft protrudes upwards on the inlet valve of the first cylinder

- Apply the valve lever pusher to remove the rocker arm.

- Remove the hydro element and install a valve adjusting screw instead.

- Reinstall the rocker arm.

- Adjust the valve adjustment screw so that the rocker arm rests firmly on the base circle of the cam.

- Attach the holder from the dial indicator to the engine so that the dial indicator pin is vertical on the valve spring retainer.

- Clamp the dial gauge with 3 - 4 mm preload in the holder.

- Turn the motor clockwise by hand until the cam presses the rocker arm of the valve 2 mm downwards

- Observe the dial indicator that is running backwards.

- Read off the number on the flywheel on the crankshaft and compare it with the number given in the table.

If correction using the last woodruff key is not possible, a new timing chain is required. To be able to replace the woodruff key, you have to remove the sprocket on the camshaft:

- The timing chain and the camshaft sprocket mark each other and connect securely with a cable tie or wire.

- Place a rag in the chain case to prevent any disc springs installed from the chain sprocket from falling into it.

- Loosen and remove the camshaft sprocket (100 Nm) by holding the shaft with a suitable wrench or pliers.

Important! A compensation washer with a marking is installed behind the camshaft gear. This must also be removed. The installation position must be observed! The marking notch on the compensating washer must be in the same place with the woodruff key when it is reinstalled.

- Remove the existing disc springs

- Insert correction disk springs. The driver's side has one, the passenger side has two disc springs every now and then.

- Install and check shim and camshaft sprocket and tighten to 100 Nm.

The deviation you measure on the left bank is not necessarily the same as that on the right bank and vice versa. The deviation of the right bank (on the passenger side) is often greater than that of the bank on the left; therefore, different correction disc springs must be installed accordingly. In the case of a minor discrepancy, it can also happen that only one bank needs to be corrected and the other can remain unchanged. (Info: www.w126-wiki.de)

In summary, the information on setting the control times:

- Timing of 4-stroke engines

- The interaction between the distributor (provides the ignition spark), the crankshaft (piston position) and the camshaft (gas exchange control) must be right.

- The crankshaft rotates at twice the speed of the camshaft / ignition distributor

- Incorrect timing prevents the engine from running. Damage from collision between pistons and valves can occur.

- Coarse adjustment: using separate adjustment marks for the position of the crankshaft, the camshaft and the distributor. They (often) relate to the ignition of the 1st cylinder.

- Crankshaft: If cylinder number 1 fires, the cylinder's piston must be in TDC. There are also markings on the swing and / or the crankshaft pulley.

- Ignition distributor: The distributor finger of the ignition distributor must point to cylinder number 1. There is almost always a notch on the distributor housing for this purpose.

- After the rough adjustment, the engine should be able to run. Next step: Exact adjustment of idling and ignition.

- If you move the distributor against the direction of rotation, the ignition advance moves in the direction of advance! The other way around, she goes in the late direction.

Instructions: "Setting control times on the car"

Of course that had not happened yet!

tuningblog has countless other articles on the subject of car and auto tuning in stock. Do you want to see them all? Just click HERE and look around. In part, we would like to provide you with news but also off the tuning. In our category Tips, products, information & Co We have reviews of car or accessories manufacturers, new ones Tuning Wiki Terms or one or the other Leak veröffentlicht. Following an excerpt of the last articles:

|

Everything about the turbocharger: function, damage, symptoms! |

"Tuningblog.eu" - we keep you up to date on the subject of car tuning and car styling with our tuning magazine and we present you the latest tuned vehicles from all over the world every day. It's best to subscribe to ours Feed and will automatically be informed as soon as there is something new about this post, and of course also to all other contributions.

tuningblog.eu Your magazine about tuning the car

tuningblog.eu Your magazine about tuning the car

This is most valuable I shared this with my technician, thank you