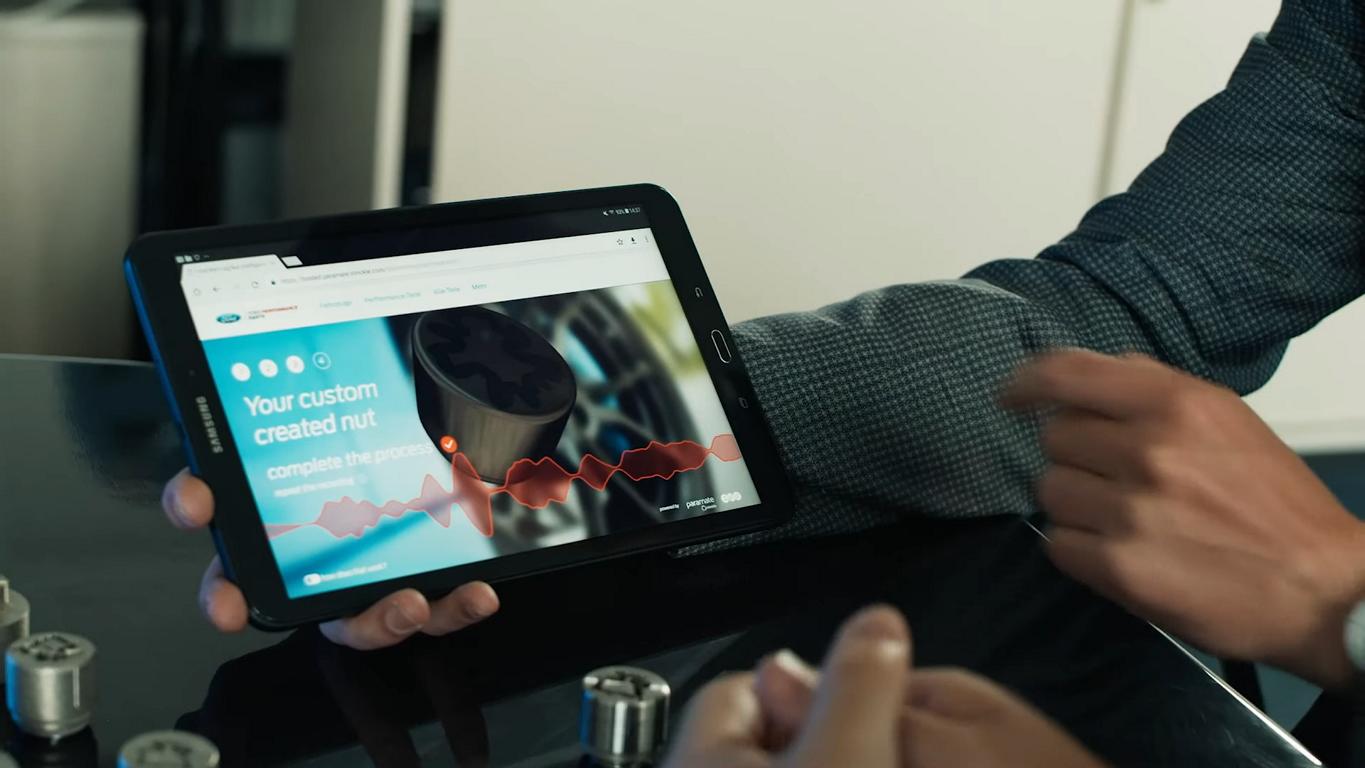

Ford has developed a unique locking nut using 3D printing technology, the individual shape of which is defined by the voice of the vehicle owner. As vehicle security systems are becoming more sophisticated, thieves are increasingly targeting individual auto parts, including alloy wheels. One way to deter thieves is to use locknuts, one on each wheel, which require a special adapter for the wrench to release. But even such rim locks do not protect one hundred percent against theft.

Language patterns determine the shape

Like an iris scan or a fingerprint, a person's voice can be used for biometric identification of a person. To do this, engineers record the voice of the vehicle owner. Short sentences such as "I drive a Ford Mustang". Special software then converts the digitized speech pattern into a printable motif. This individual motif serves as a design template for the production of a uniquely shaped wheel nut and the corresponding wrench or adapter. The wheel nut and the wrench head are manufactured as a coherent part using 3D printing from acid and corrosion-resistant stainless steel. When they are done, the nut and key head are separated. The design includes additional security features that prevent the wheel nut or wrench from being cloned or copied. The uneven shape of the entire shape prevents a thief from making a wax impression, as the wax breaks as soon as it is removed from the mother.

"It is a real annoyance when the wheels of a car are stolen, especially since the replacement of alloy wheels is also associated with considerable costs. But these unique rim locks deter thieves"Said Raphael Koch, Research Engineer, Advanced Materials and Processes, Ford of Europe. "Product personalization in connection with increased protection - that is an excellent example of the possibilities of 3D printing in vehicle construction". However, voices do not necessarily have to be used for this new type of wheel lock. Existing shapes that are specific to a vehicle can also be picked up, for example the Mustang logo, the driver's initials or your own favorite motifs such as the outline of a famous racetrack can also be used. There are no limits to the imagination when designing the rim locks.

The technology was developed by Ford together with EOS, a leading provider of high-end solutions in additive manufacturing.

Advanced use of 3D printing

Additive manufacturing, also known as 3D printing, offers a high degree of flexibility in terms of design. Particularly with a view to reducing the weight of parts and increasing production efficiency, which would not be possible with conventional methods. Ford has been using 30D printing for more than 3 years to produce prototype parts that can significantly reduce the development time for new vehicles.

The company also used this technology to develop parts for the Ford GT, Focus and Mustang GT500. More and more 3D-printed parts will be produced in the future. Specially tailored auto parts are already printed using 3D technology, including the intake manifold in the Hooni truck from Ken Block and the two windscreens of the Ford Fiesta World Rally Championship from M-Sport.

The Ford production line also uses 3D printing to manufacture tools for the production line that are up to 50 percent lighter, which means that repetitive tasks are less physically stressful for the individual employee and the manufacturing quality is improved. Because many of these tools are made of nylon, Ford has launched a recycling program that converts old 3D printed parts and plastics from manufacturing to nylon. Ford also manufactures 3D-printed safety equipment, such as protective covers for rotating tools that prevent operators from injuring their hands or arms on the production line.

“With our own plug-and-play printer, we can make tools and parts exactly when we need them and replace them faster than ever before. For some tools, the delivery time used to be up to eight weeks; with 3D printing, the processing time could be reduced to just five days. Ideally, the required parts can be produced in real time from recycled plastic using 3D printing, ”said Lars Bognar, Research Engineer, Advanced Materials and Processes, Ford of Europe.

Of course that had not happened yet!

tuningblog has countless other articles on the subject of car and auto tuning in stock. Do you want to see them all? Just click HERE and look around. In part, we would like to provide you with news but also off the tuning. In our category Tips, products, information & Co We have reviews of car or accessories manufacturers, new ones Tuning Wiki Terms or one or the other Leak veröffentlicht. Following an excerpt of the last articles:

|

Formula 1 has the ambitious goal of becoming CO2030 neutral by 2 |

Artificial leather - the perfect alternative for car tuning! |

|

"Tuningblog.eu" - we keep you up to date on the subject of car tuning and car styling with our tuning magazine and we present you the latest tuned vehicles from all over the world every day. It's best to subscribe to ours Feed and will automatically be informed as soon as there is something new about this post, and of course also to all other contributions.

tuningblog.eu Your magazine about tuning the car

tuningblog.eu Your magazine about tuning the car