The Transmission are an essential component for the performance and efficiency of the vehicle. They are responsible for transmitting the power generated by the engine to the wheels, thereby allowing the driver to Speed as well as the Direction of travel to control. Due to its central role in vehicle mechanics, there are a variety of transmission types, each with its own distinctive features and each with specific maintenance requirements. The gear types range from manual and automatic up to semi-automatic and stepless Driven, with each system delivering a specific driving experience and maintenance profile. Not to forget that SMG transmission. So let's get started with the topic of gearbox types and maintenance!

Types of gearboxes and maintenance

- Instructions & maintenance, from manual transmission

- Instructions & maintenance, from automatic transmission

- Instructions & maintenance, semi-automatic

- Instructions & maintenance, dual clutch transmission

- Instructions & Maintenance, Continuously Variable Transmission (CVT)

- Instructions & Maintenance, SMG Transmissions

- Manual transmissions are among the oldest and simplest types of gears. They require the driver to change gears manually, which is often perceived as more “real” and controlled. In a manual transmission, the gears move along an axis and mesh to produce different gears. Maintenance of a manual transmission includes regular checks of the gear oil, which provides lubrication and reduces wear.

- Automatic transmission provide more comfort as they change gears automatically. They use a complex system of planetary gears, hydraulic controls and torque converters. Maintaining an automatic transmission involves changing the gearbox regularly gear oil and the filter. It is important to pay attention to signs such as delayed gear changes or unusual noises as these can indicate problems.

Semi-automatic, double clutch, continuously variable...

- Semi-automatic transmissions and Dual-clutch transmission are modern shapes that enable faster gear shifting. Dual clutch transmissions use two separate clutches for even and odd gears, often allowing for a seamless transition and improved acceleration. Maintenance of transmission types includes regular checks of the clutch system and transmission oil.

- Continuously variable transmission (CVT) provide a continuous variation of the gear ratios. They use a belt and pulley to provide smooth gear changes. This results in a smoother driving experience and improved fuel efficiency. The maintenance of one CVT includes checking the transmission belt and oil to ensure everything is running smoothly.

The SMG transmission is also special

BMW's Sequential M Gearbox (SMG) is a form of manual transmission that is a mixture of manual control and automated switching processes offers. It uses an electro-hydraulic system to control the shifting process, allowing for quick and precise gear changes. The SMG transmission is known for its performance and allows you to change gears either via shift paddles on the steering wheel or by operating the gear knob.

Instructions & maintenance, from manual transmission

The right driving behavior: A key element in maintaining your manual transmission is your personal driving style. To ensure a long service life for the manual transmission, the following behavior is recommended:

- Clean switching: Depress the clutch pedal fully and engage the gears without applying strong pressure.

- Anticipatory driving: Avoid unnecessary gear changes.

- Correct use of reverse gear: Only engage reverse gear when the vehicle is completely stationary.

- Avoidance of clutch loads: Avoid depressing the clutch continuously at traffic lights or while driving; use idle instead.

- Use of the engine brake: This is recommended for manual transmissions.

- No laying on the gear lever: This prevents earlier gear wear.

- Starting on the mountain: Use the brake or handbrake to avoid unnecessary strain on the clutch.

- Regularly check the oil level: Look for changes in smell, color and consistency.

- Timely oil change: primarily when there are abnormalities such as noises or jerking.

- Watch out for warning signs: Cracking, humming, rattling noises or irregularities when switching.

- Professional diagnosis: If there are any signs of problems, you should visit a workshop.

- Follow the manufacturer's instructions: Check the service booklet for specific intervals.

- Regular inspections: These make it possible to identify and correct problems at an early stage.

- Obtaining the manufacturer's warranty: by adhering to maintenance intervals.

Instructions & maintenance, from automatic transmission

- Make sure the engine is off when there is no oil in the transmission and avoid towing the vehicle in this condition.

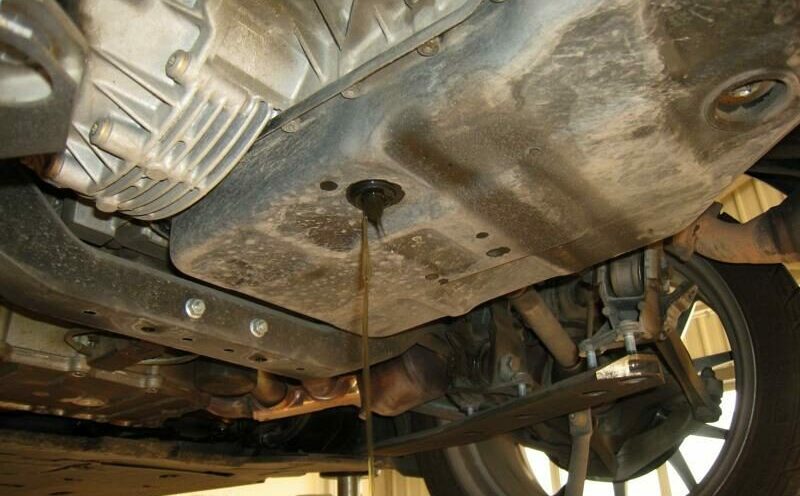

- Step 1: Drain Oil: Remove all necessary trim parts from the underbody. Let the old oil over the Oil drain plug on the bottom of the oil pan. Note that oil that smells burnt or has chips or metal fragments in it indicates a defect.

- Step 2: Remove oil pan: The Metal oil pans replace only the oil filter and sealing ring. Loosen the screws in the specified order and clean the tray and the permanent magnet. Then install the new oil filter. At Plastic oil pans: a complete replacement takes place.

- Step 3: Install the oil pan: Install the new or cleaned oil pan with new screws. Pay attention to the order and tightening torque specified by the manufacturer. When using one Oil change kits All required parts are included.

- Step 4: Install the drain plug: Install the new drain plug with a new gasket and pay attention to the specified tightening torque.

- Step 5: Fill in gear oil: Fill the gearbox carefully with the correct oil on. Avoid using additives or cleaners that could alter the chemical composition of the oil.

- Step 6: Run the engine and shift through gears: Start the engine in neutral and shift through the gears, depending on your transmission variant. This helps fill the torque converter with oil and ensure that the transmission fluid is circulating properly.

- Step 7: Check oil temperature and filling quantity: Check the oil temperature. Ensure correct level and refill if necessary. Close the filling screw when only a few drops come out.

- Step 8: Completing the Oil Change: After you have tightened the filling screw, you can switch off the engine. The oil change is now complete.

Instructions & maintenance, semi-automatic

- Step 1: Understanding Semi-Automatic Transmission: Find out about the special features of the semi-automatic transmission.

- Step 2: Periodic Transmission Fluid Check: Check the oil level and the quality of the gear oil regularly. Look for changes in color or consistency, or unusual smells.

- Step 3: Perform an oil change: Change the oil at the intervals recommended by the manufacturer. Use the gear oil specified for your gearbox.

- Step 4: Check clutch system: Regularly check the clutch system, especially the wear of the clutch discs. Watch for signs of poor clutch performance, such as slipping or delayed response.

- Step 5: Software Updates: Pay attention to available software updates for the semi-automatic transmission. Software updates can improve performance and efficiency.

- Step 6: Change transmission filter: Change the transmission filter according to the manufacturer's instructions. A clean filter is crucial for efficient transmission function.

- Step 7: Check electronic components: Regularly check the transmission's electronic components, such as sensors and actuators. Pay attention to error messages in the vehicle diagnostic system.

- Step 8: Inspect Drivetrain: Inspect the entire drivetrain, including driveshafts and differential. Listen for any unusual noises or vibrations.

- Step 10: Adjust driving behavior: Adapt your driving behavior to protect the semi-automatic transmission. Avoid hard accelerations and abrupt shifting.

Instructions & maintenance, dual clutch transmission

- Step 1: Preparing for Oil Change: Follow the vehicle manufacturer's instructions carefully. Make sure the engine is turned off before you begin changing the oil.

- Step 2: Drain Oil: Remove the necessary trim parts from the underbody. Let the old oil over the Oil drain plug off and catch it.

- Step 3: Checking the old gear oil: Check the drained oil for signs of wear, such as a burnt smell or metal shavings.

- Step 4: Replacing the oil filter (on wet clutch transmissions): In wet clutch transmissions, the oil filter usually needs to be replaced every 60.000 km. If necessary, remove the battery and air filter box to access the oil filter.

- Step 5: Filling the transmission with new oil: Carefully fill the transmission with the specific DSG transmission oil. For wet clutch transmissions, use about 5 liters of oil.

- Step 6: Run the engine and shift through gears: Start the engine and engage each selector lever position for a few seconds while pressing the brake. Monitor the transmission oil temperature and adjust the oil level accordingly.

- Step 7: Checking and adjusting the oil level: Check the oil level at the specified transmission oil temperature. Make sure the transmission contains the correct amount of oil.

- Step 8: Completing the Oil Change: Tighten the oil drain plug to the specified tightening torque.

Instructions & Maintenance, Continuously Variable Transmission (CVT)

- Step 1: Understanding CVT Transmission: Find out about the functionality and special features of your specific CVT transmission. Note that CVT transmissions have a different design and operating principles compared to conventional automatic transmissions.

- Step 2: CVT Transmission Fluid Check: Regularly checking the transmission fluid is critical to the health of the CVT transmission. Check the oil level and the quality of the oil (color, smell, consistency).

- Step 3: Performing an Oil Change: Perform oil changes at the recommended intervals, which may vary depending on the manufacturer. Only use transmission oil specified for CVT transmissions.

- Step 4: Cleaning the Transmission Filter: Check and clean the transmission filter or replace if necessary. A clean filter contributes to the efficient functioning of the CVT transmission.

- Step 5: Adjusting the transmission electronics: Watch for software updates that can improve the performance and efficiency of the CVT transmission. Electronic components should be checked regularly and updated as necessary.

- Step 6: Checking CVT Components: Regularly inspect key components such as belts, pulleys and pressure valves. Look for signs of wear or damage.

- Step 7: Diagnosing CVT-Specific Problems: Look for symptoms such as jerking, unusual noises, or delayed response, which may indicate CVT problems. If you suspect problems, you should visit a specialist workshop.

- Step 8: Professional Inspection and Maintenance: Have your CVT transmission checked and serviced regularly by professionals. Expert inspections can help identify and correct problems early.

Instructions & Maintenance, SMG Transmissions

- Introduction to maintenance of the SMG 2 gearbox: The Sequential M Gearbox 2 (SMG 2) requires regular maintenance to ensure optimal performance. An important aspect of maintenance is changing the hydraulic oil, which is recommended every five years.

- Step 1: Preparing for Oil Change: Prepare the following tools and materials: suction syringe, diagnostic software for system bleeding, 1 liter of suitable hydraulic oil, open ring spanner SW11, hose with an inner diameter of approximately 11 mm, container for at least 600 ml.

- Step 2: Avoiding dry running of the hydraulic pump: To avoid dry running, disconnect the SMG relay from the engine control unit.

- Step 3: Removing Old Hydraulic Oil: Use the suction syringe to suck the old hydraulic oil from the reservoir container in the engine compartment.

- Step 4: Fill with new hydraulic oil: Refill the reservoir container with new hydraulic oil.

- Step 5: Disconnecting the hydraulic line: Disconnect the hydraulic line on the slave cylinder under the vehicle. Attach a hose to the loosened hydraulic line to allow the old oil to flow into the prepared container.

- Step 6: Reinstalling the SMG Relay: Plug the SMG relay back in.

- Step 7: Flushing the System: Use diagnostic software to control the clutch valve. Do this until no more used oil comes out of the hose. Monitor reservoir level and refill as necessary.

- Step 8: Bleeding the Hydraulic System: Finally, bleed the hydraulic system using the diagnostic software.

Conclusion: Types of gearboxes and their maintenance

The right Maintenance of gearboxes is crucial for the longevity and reliability of the vehicle. Regular inspections and oil changes help minimize internal wear and maximize performance. However, it is important to pay attention to the specifications and maintenance intervals recommended by the manufacturer. Inadequate maintenance can lead to serious problems including Gearbox damage and expensive repairs.

The following note is essential: For safety reasons, tuningblog recommends all repair, inspection and maintenance work exclusively to be carried out in a specialist workshop! Although our information is summarized to the best of our knowledge and belief, we cannot assume any liability for the content. All information is therefore "without guarantee".

That wasn't it yet!

In our Auto Repair Category you will find advice and instructions on common vehicle defects, repairs and the installation of accessories/tuning parts.

tuningblog.eu Your magazine about tuning the car

tuningblog.eu Your magazine about tuning the car