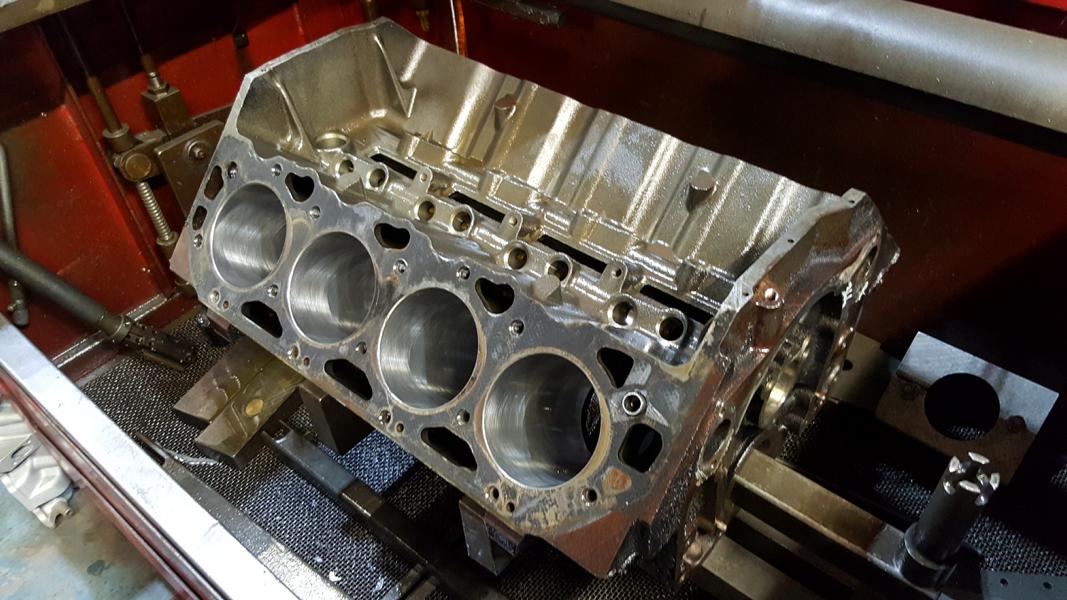

Porting cylinders, a veritable art in the world of engine tuning, is a practice aimed at increasing the performance and efficiency of combustion engines. The technology mainly concerns the modification of the Inlet and outlet channels of the cylinder, also known as “ports”, to optimize the airflow and fuel mixture in the engine. The process begins with a detailed examination of the cylinder heads. The heads, usually made of aluminum or cast iron, have the intake and exhaust valves as well as the channels that guide air and fuel into the combustion chambers and exhaust gases out of the engine. However, when shipped from the factory, the channels may have small irregularities that disrupt the airflow.

Porting cylinders

The goal of porting is to eliminate such obstructions and create a smoother, more efficient air path that requires no (or less) Turbulence generated. A key component in the process is the Contouring the channels. By removing excess material and polishing the interior walls of the port, the channels can be shaped to allow optimal airflow. The size and shape of the adjustments vary depending on the performance target and engine type. At the inlet side The focus is on efficiently directing the air and fuel mix into the combustion chamber. The ports can enlarged and their Shape optimized to maximize airflow. This leads to better filling of the cylinders and thus to a More efficient.

Cylinder ports + timing

The outlet side On the other hand, the aim is to efficiently remove the exhaust gases from the combustion chamber. By smoothing and adjusting the channels, the flow of exhaust gases is accelerated, reducing backlog and improving overall performance. During porting they are also Valve seats and Valve guides of great importance. These must be machined precisely to ensure optimal sealing and guidance of the valves. Adjusting the valve seats can also improve the flow characteristics within the channels. The Sizing the ports is, however, a critical aspect. Excessive magnification can also negative impacts have, like one reduced speed of the air flow, which can reduce cylinder filling and therefore performance. Therefore, accurate coordination is crucial.

The surface quality is important!

Another important consideration is this surface finish the ports. A surface that is too smooth can affect fuel evaporation, while one that is too rough can disrupt airflow. Therefore is a middle way required for optimal results. All in all, that is Cylinder porting a demanding task that requires in-depth technical understanding and precision. It's not just a matter of removing material, but rather a detailed optimization of the airflow dynamics within the engine. However, the modification can significant performance improvements .

Instructions: Basics of cylinder porting for laypeople

Important note: This guide provides a general overview of cylinder porting and is by no means a detailed or comprehensive guide. Implementation requires specialized tools and in-depth knowledge in engine technology. It is recommended to carry out the work only if you have appropriate experience:

- Step 1: Preparation and safety: Make sure you have all the necessary tools and protections on hand. This includes turning tools, milling cutters, grinding heads, safety glasses and gloves. Prepare a clean and well-lit workspace.

- Step 2: Dismantling the cylinder head: Remove the cylinder head from the engine block. This usually requires loosening screws and removing various components such as the valve cover, spark plugs and possibly the camshaft.

- Step 3: Cleaning and inspection: Thoroughly clean the cylinder head to remove any deposits. Inspect the inlet and outlet channels for irregularities and mark areas to be addressed.

- Step 4: Planning porting: Plan how much material to remove. Please note that removing too much material can have negative effects.

- Step 5: Rough processing of the channels: Start by rough-editing the channels. Carefully remove material to widen the channels and clear any obstructions.

- Step 6: Fine work and polishing: After the rough machining, the fine work takes place. Smooth the surfaces and ensure that the channels have an even shape. Polish the channels to optimize the surface finish. Be careful not to make the channels too slippery.

- Step 7: Checking and adjusting the valve seats: Check valve seats and make adjustments if necessary to ensure optimal sealing and performance.

- Step 8: Final inspection and assembly: Carry out a thorough inspection of all areas being worked on. Install the cylinder head back onto the engine block. Pay attention to the correct tightening sequence and the tightening torque of the screws.

- Step 9: test run: After assembly, carry out a test run to check the function and increase in performance.

Additional recommendations:

- Document each step so that you can trace the original status if necessary.

- If you encounter any confusion or difficulty during the process, do not hesitate to consult a professional.

- Cylinder porting is a demanding task that requires patience and precision. This guide is intended to provide an initial insight, but does not replace the detailed instructions and experience of a professional engine builder.

Additional tuning modifications related to cylinder porting:

Cylinder porting is an essential part of engine tuning, but to achieve its full potential, further modifications should be considered. These additional modifications can further increase the engine's performance and efficiency. Here is an overview:

- Camshaft upgrade: A more powerful camshaft can improve valve timing and lift, which, when combined with ported cylinders, significantly increases engine performance.

- Valve and valve spring upgrades: Larger valves increase airflow, while stronger valve springs withstand higher speeds and more aggressive cam profiles.

- Piston and Connecting rods: High-performance pistons and connecting rods increase the load capacity and efficiency of the engine, especially at higher power and speeds.

- head gasket and cylinder head screws: A reinforced head gasket and high-strength cylinder head bolts are important to ensure reliability under increased cylinder pressure.

- air intake: An optimized intake system, including the air filter and intake manifold, can improve airflow, which is especially important when porting the engine to handle more air.

- Exhaust system: A more powerful exhaust system, including Headers and Sports exhaust system, reduces exhaust back pressure and improves exhaust flow, increasing power and efficiency.

- Fuel system upgrade: A high-performance fuel pump, larger injectors and optimized fuel pressure control are necessary to meet the engine's higher fuel requirements.

- Engine control unit (ECU) tuning: Reprogramming or replacing the ECU (chip tuning) is crucial to unlocking the full potential of mechanical upgrades. Custom fuel maps, ignition timing and other parameters are essential for maximum performance and reliability.

- Intercooler upgrade: For turbocharged engines, a larger or more efficient intercooler can improve intercooling, resulting in better performance.

- Turbo- or Compressor upgrade: For turbocharged engines, replacing the turbocharger or supercharger for a larger or more efficient model can significantly increase performance.

- Cooling system upgrade: A high-performance radiator and improved cooling components help keep engine temperatures under control, particularly important on tuned engines.

- Lightweight components: The use of lightweight components, such as a light flywheel or lighter wheels, can improve engine response and increase overall performance.

Each of the modifications should be carefully planned and tailored to the desired goals and needs of the vehicle. It is also important to consider the overall tuning of the engine to ensure that all components work together in harmony.

That wasn't it yet.

Planned changes to the law, traffic violations, current regulations in the area of the STVO, etc.? You can find everything about this in the category "Test sites, laws, offenses, information".

tuningblog.eu Your magazine about tuning the car

tuningblog.eu Your magazine about tuning the car