FAQ about turbocharger and compressor repairs

1. Why is repairing a turbocharger often better than completely replacing it?

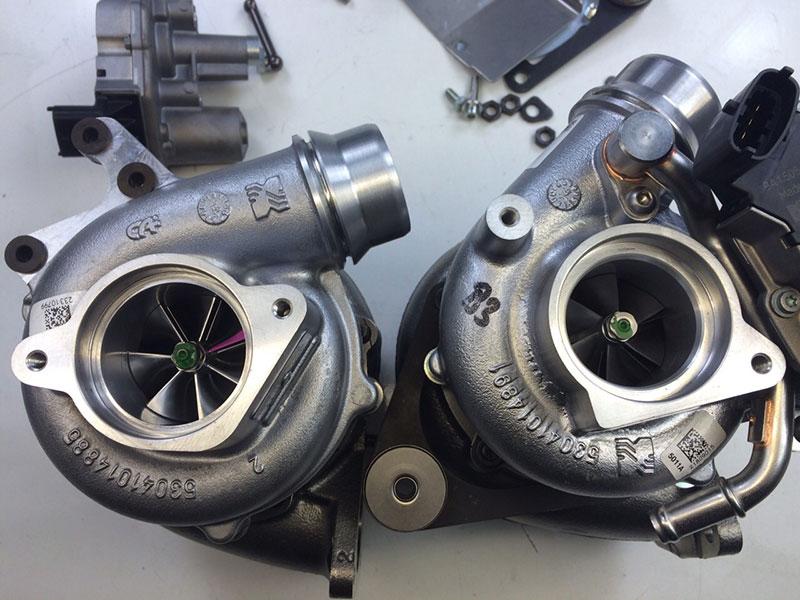

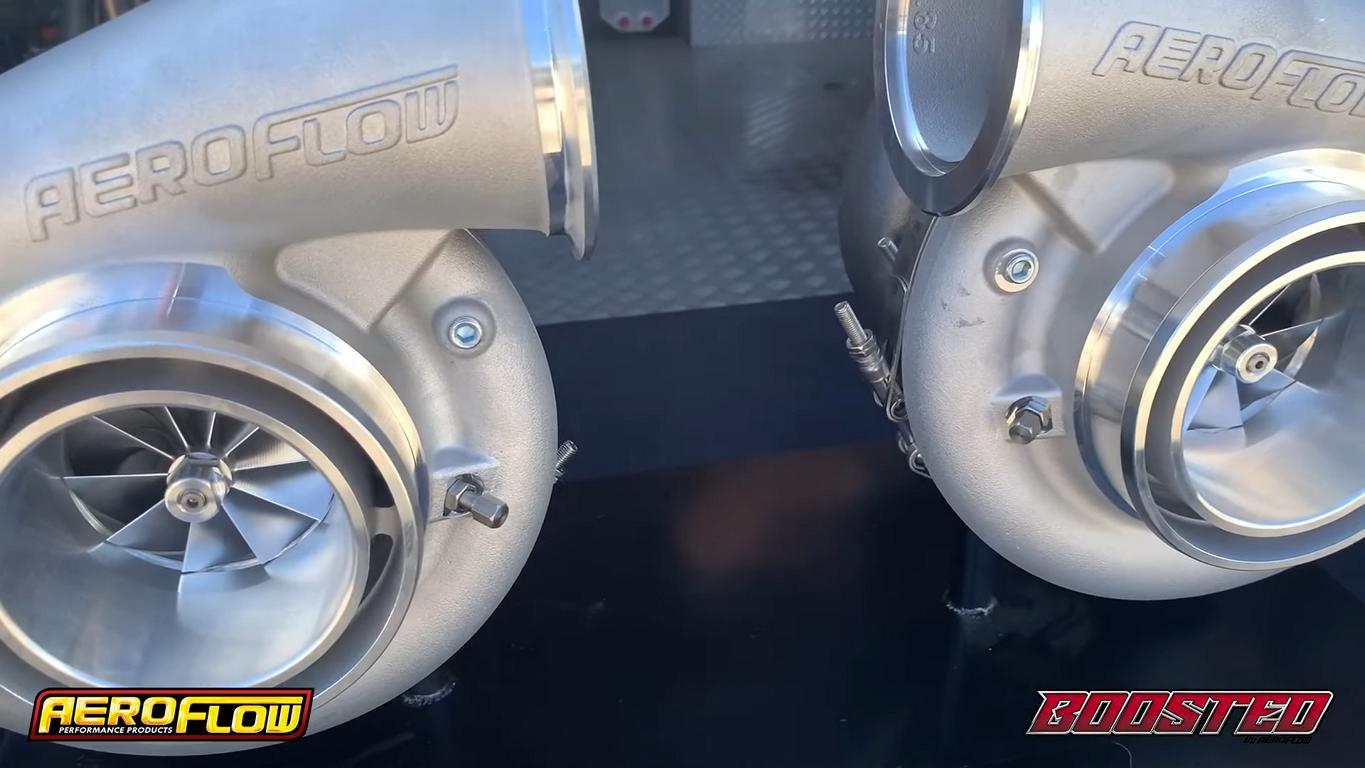

- Repairing a turbocharger can be significantly cheaper than replacing the entire component. Turbochargers, common in modern gasoline and diesel engines, can often be repaired, even if they are highly complex and cost up to 300.000 U / min rotate. The repair focuses on specific damage, which is often cheaper than a complete replacement.

2. What are common causes of turbocharger damage?

- Common causes of damage to turbochargers are: Lubrication problems, which can lead to scoring on the turbocharger shaft. Also Imbalances, caused by damage to turbo or compressor wheels, Over-winding damage or damage caused by foreign bodies is typical. With VTG loaders, the guide vanes sticking due to soot can also be a problem.

3. What symptoms indicate turbocharger damage?

- Signs of turbocharger damage can Oil loss, smoking exhaust, power loss or Whistling noises be out of the area of the manifold. If you experience these symptoms, turbocharger damage should be considered.

4. How are parts of a defective turbo reused?

- Defective turbochargers are often repaired, with working components being reused. After the overhaul, these loaders are tested on a test bench and can even be used with up to three years guarantee Tobe offered. This reduces waste and is a cost-effective solution.

5. How much does it cost to repair or replace a turbocharger?

- The costs for repaired turbochargers vary depending on the model 200 and 600 euros, while a new part often costs more than twice as much. However, this does not include the costs for installation and removal.

6. Why is it important to identify the cause of turbo failure?

- Simply replacing the turbo without addressing the underlying cause can lead to repeated damage. It is therefore crucial to diagnose and correct the exact cause of the defect before installing a new or reconditioned turbo.

7. Can damage to the turbo control system be easily repaired?

- Damage to the turbocharger control system, such as the diaphragm, spring or actuating mechanism Vacuum unit, are often less dramatic and can usually be repaired without replacing the entire turbocharger unit.

8. What should be taken into account when maintaining turbochargers?

- When servicing turbochargers, it is important to ensure good lubrication and cooling to prevent damage. Regular inspections of the oil lines and cooling system are crucial to maintaining the lifespan and efficiency of the turbocharger.

9. What role does electronics play in modern turbochargers?

- The electronic control of modern turbochargers is complex and requires specialized knowledge for diagnosis and repair. Especially with turbos variable turbine geometry (VTG) The correct functioning of the electronic components is crucial for the performance of the charger.

10. How does a defective turbocharger affect the engine?

- Damage to the turbocharger that is not recognized in time can lead to further damage to the engine. Parts of the turbocharger can become loose and enter the engine, causing serious engine damage. Therefore, early diagnosis and repair is essential.

The following note is essential: For safety reasons, tuningblog recommends all repair, inspection and maintenance work exclusively to be carried out in a specialist workshop! Although our information is summarized to the best of our knowledge and belief, we cannot assume any liability for the content. All information is therefore "without guarantee".

That wasn't it yet!

In our Auto Repair Category you will find advice and instructions on common vehicle defects, repairs and the installation of accessories/tuning parts.

tuningblog.eu Your magazine about tuning the car

tuningblog.eu Your magazine about tuning the car